ZHCSAG8A November 2012 – March 2015 DRV10866

PRODUCTION DATA.

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

DRV10866 only requires three external components. The device needs a 2.2-μF or higher ceramic capacitor connected to VCC and ground for decoupling. During layout, the strategy of ground copper pour is very important to enhance the thermal performance. For two or more layers, use eight thermal vias. Refer to Layout Example for an example of the PCB layout. If there is no COM pin on the motor, one can be simulated. Use three resistors connected in a wye formation, one connected to U, one to V, and one to W. Connect the resistor ends opposite of the phases together. This center point is COM. To find the proper resistor value, start with a value of 10 kΩ and continue to decrease by 1 kΩ until the motor runs properly.

8.2 Typical Application

Figure 4. Typical Application Schematic

Figure 4. Typical Application Schematic

8.2.1 Design Requirements

For this design example, use the parameters listed in Table 2 as the input parameters.

Table 2. Recommended Application Range

| MIN | TYP | MAX | UNIT | ||

|---|---|---|---|---|---|

| Motor voltage | 1.6 | 5.5 | V | ||

| VCC capacitor | Place as close to the pin as possible | 2.2 | µF | ||

| Operating current | Running with normal load at rated speed | 500 | mA | ||

| Absolute max current | During start-up and locked motor condition | 650 | mA | ||

8.2.2 Detailed Design Procedure

- Refer to the Design Requirements and ensure the system meets the recommended application range.

- Ensure the VCC level is in between 1.6 and 5.5 V

- Verify the motor needs no more than 500 mA during runtime.

- Follow the application and Power Supply Recommendations when constructing the schematic.

- Make sure there is adequate capacitance on VCC.

- Size the resistor on CS according to the details given in Feature Description.

- Use a pullup on FG.

- If the motor doesn’t have a common pin, create one using the method listed in Application Information.

- Build the hardware according to the Layout Guidelines.

- Test the system with the application's motor to verify proper operation.

8.2.3 Application Curves

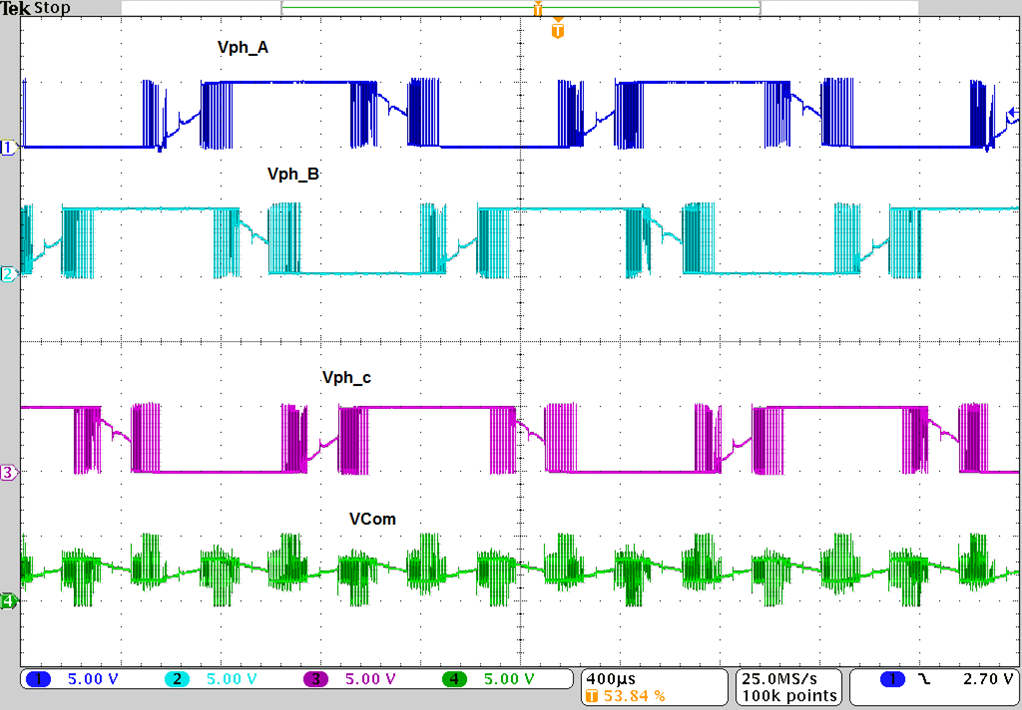

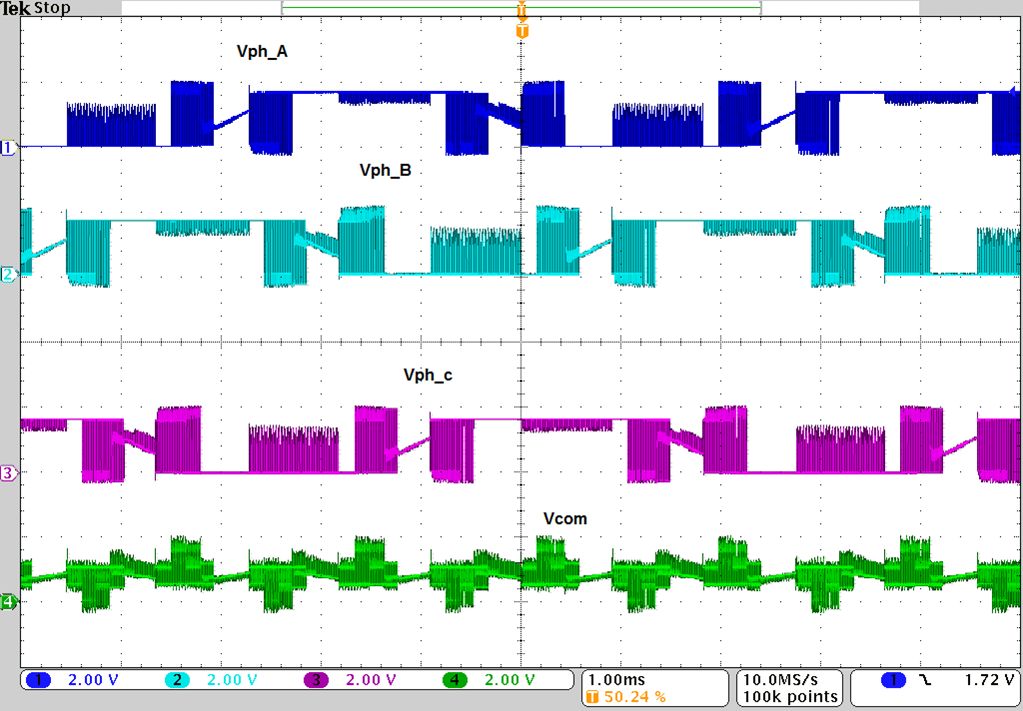

Figure 5. Normal Operation With Vcom at 5 V

Figure 5. Normal Operation With Vcom at 5 V

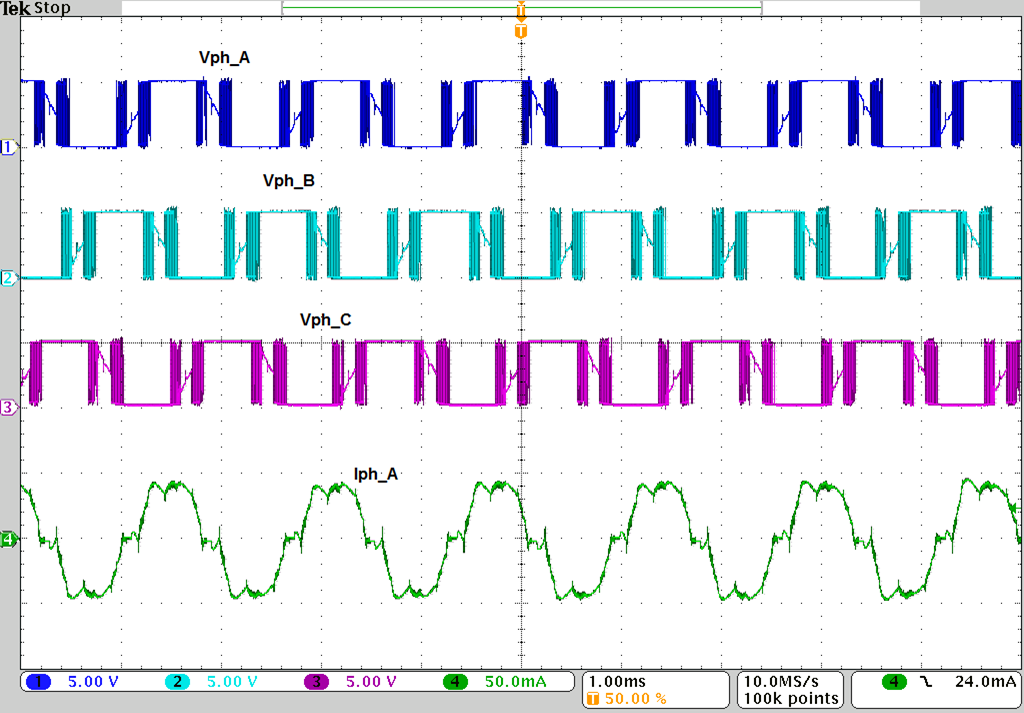

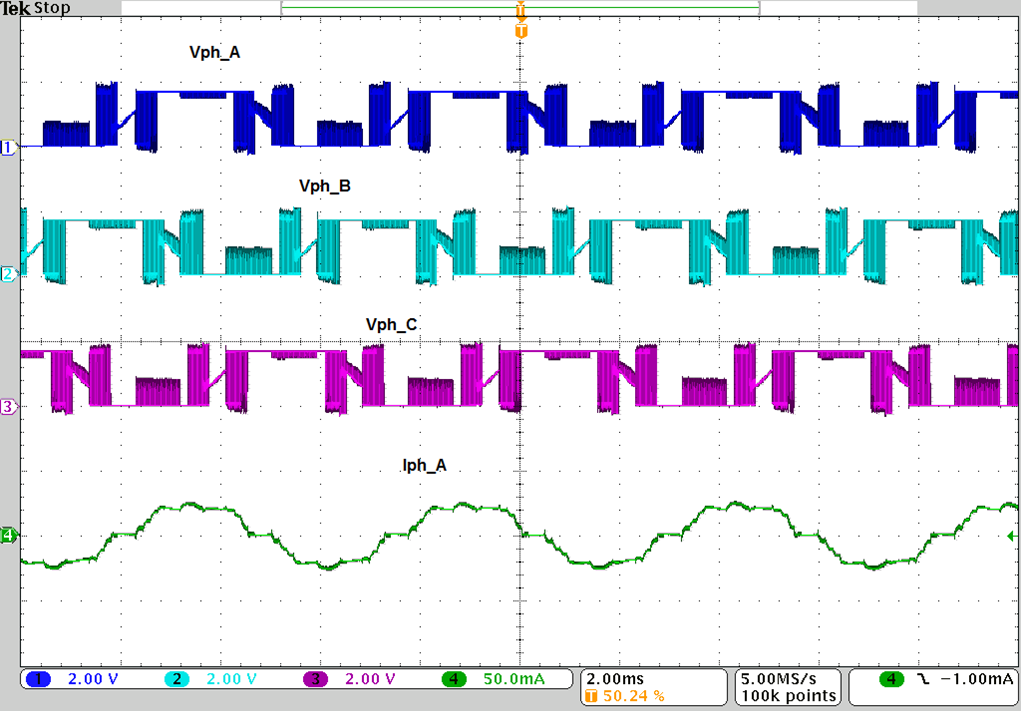

Figure 7. Normal Operation With 3-Phase Voltage and

Figure 7. Normal Operation With 3-Phase Voltage and ph-A Current at 5 V

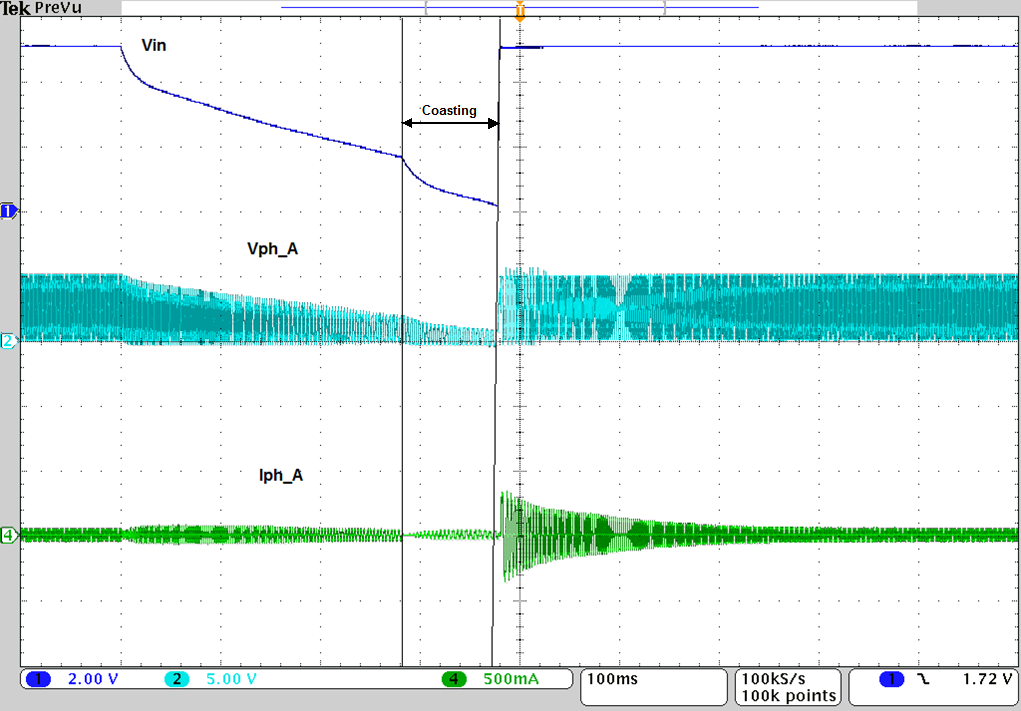

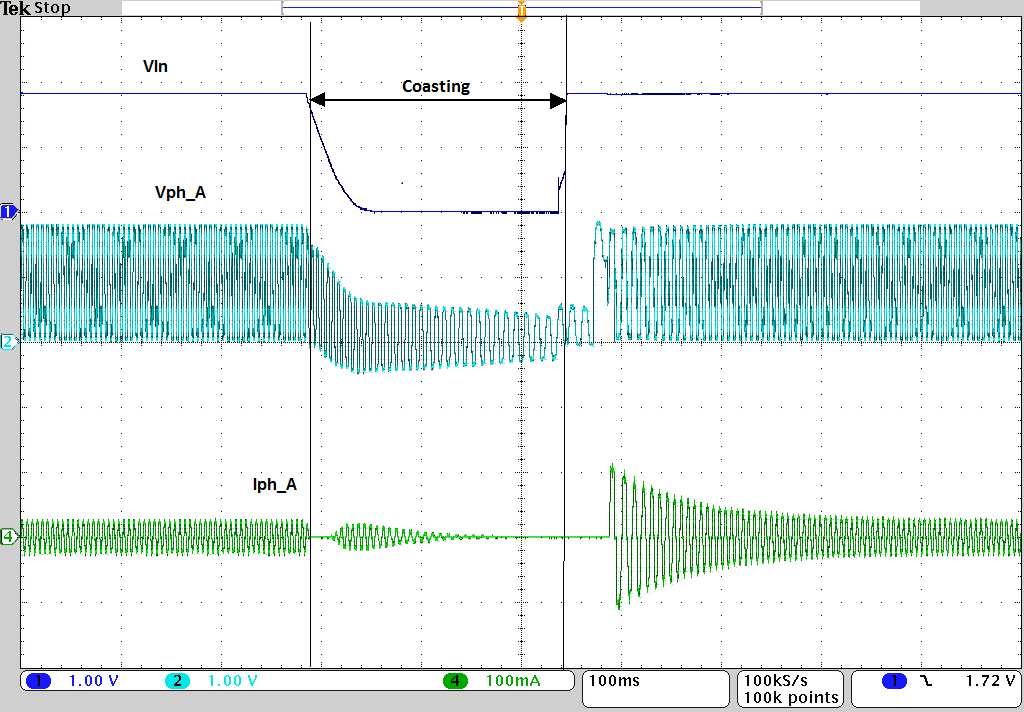

Figure 9. Re-Synchronizing to Spinning Motor During Power On-Off Cycle at 5 V

Figure 9. Re-Synchronizing to Spinning Motor During Power On-Off Cycle at 5 V

Figure 11. Start-Up at 100% Duty Cycle

Figure 11. Start-Up at 100% Duty Cycle

Figure 13. Normal Operation at 100% Duty Cycle

Figure 13. Normal Operation at 100% Duty Cycle

Figure 15. Lock Protection

Figure 15. Lock Protection

Figure 17. Clamp Voltage at Standby Mode

Figure 17. Clamp Voltage at Standby ModeEnlarged View

Figure 6. Normal Operation With Vcom at 1.65 V

Figure 6. Normal Operation With Vcom at 1.65 V

Figure 8. Normal Operation With 3-Phase Voltage and

Figure 8. Normal Operation With 3-Phase Voltage and ph-A Current at 1.65 V

Figure 10. Re-Synchronizing to Spinning Motor During Power On-Off Cycle at 1.8 V

Figure 10. Re-Synchronizing to Spinning Motor During Power On-Off Cycle at 1.8 V

Figure 12. Start-Up at 10% Duty Cycle

Figure 12. Start-Up at 10% Duty Cycle

Figure 14. Normal Operation at 50% Duty Cycle

Figure 14. Normal Operation at 50% Duty Cycle

Figure 16. Clamp Voltage at Standby Mode

Figure 16. Clamp Voltage at Standby Mode