ZHCSFO8C July 2016 – September 2023 INA250-Q1

PRODUCTION DATA

- 1

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Applications and Implementation

- 9 Device and Documentation Support

- 10Mechanical, Packaging, and Orderable Information

7.3.3 Temperature Stability

System calibration is common for many industrial applications to eliminate initial component and system-level errors that may be present. A system-level calibration may reduce the initial accuracy requirement for many of the individual components because the calibration procedure eliminates these errors associated with the components Performing this calibration may enable precision measurements at the system calibration temperature, but as the system temperature changes as a result of external ambient changes or self heating, measurement errors are reintroduced. Without using accurate temperature compensation in addition to the initial adjustment, the calibration procedure is ineffective in accounting for these temperature-induced changes. One of the primary benefits of the very-low-temperature coefficient of the INA250-Q1(including the integrated current-sensing resistor and current-sensing amplifier) is that the device measurement remains highly accurate, even when the temperature changes throughout the specified temperature range.

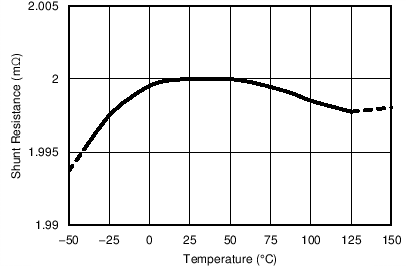

The drift performance of the integrated current-sensing resistor is shown in Figure 7-3. Although several temperature ranges are specified in the Electrical Characteristics table, applications operating in ranges other than those described may use Figure 7-3 to determine how much variance in the shunt resistor value may be expected. As with any resistive element, the tolerance of the component varies when exposed to different temperature conditions. For the current-sensing resistor integrated in the INA250-Q1, the resistor varies more when operating in temperatures ranging from –40°C to 0°C than when operating in ranges from 0°C to +125°C. However, even in the –40°C to 0°C temperature range, the drift is still low at 25 ppm/°C.

Figure 7-3 Sensing Resistor vs Temperature

Figure 7-3 Sensing Resistor vs TemperatureAn additional aspect to consider is that when current flows through the current-sensing resistor, power dissipates across this component. This dissipated power results in an increase in the internal temperature of the package, including the integrated sensing resistor. This resistor self-heating effect results in an increase of the resistor temperature helping to move the component out of the colder, wider drift temperature region.