ZHCS518E April 1998 – June 2019 LM2588

PRODUCTION DATA.

- 1 特性

- 2 典型 应用

- 3 说明

- 4 修订历史记录

- 5 Pin Configurations

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Ratings

- 6.4 Electrical Characteristics: 3.3 V

- 6.5 Electrical Characteristics: 5 V

- 6.6 Electrical Characteristics: 12 V

- 6.7 Electrical Characteristics: Adjustable

- 6.8 Electrical Characteristics: All Output Voltage Versions

- 6.9 Typical Characteristics

- 7 Detailed Description

- 8 Application and Implementation

- 9 Layout

- 10器件和文档支持

- 11机械、封装和可订购信息

封装选项

机械数据 (封装 | 引脚)

散热焊盘机械数据 (封装 | 引脚)

- KTW|7

订购信息

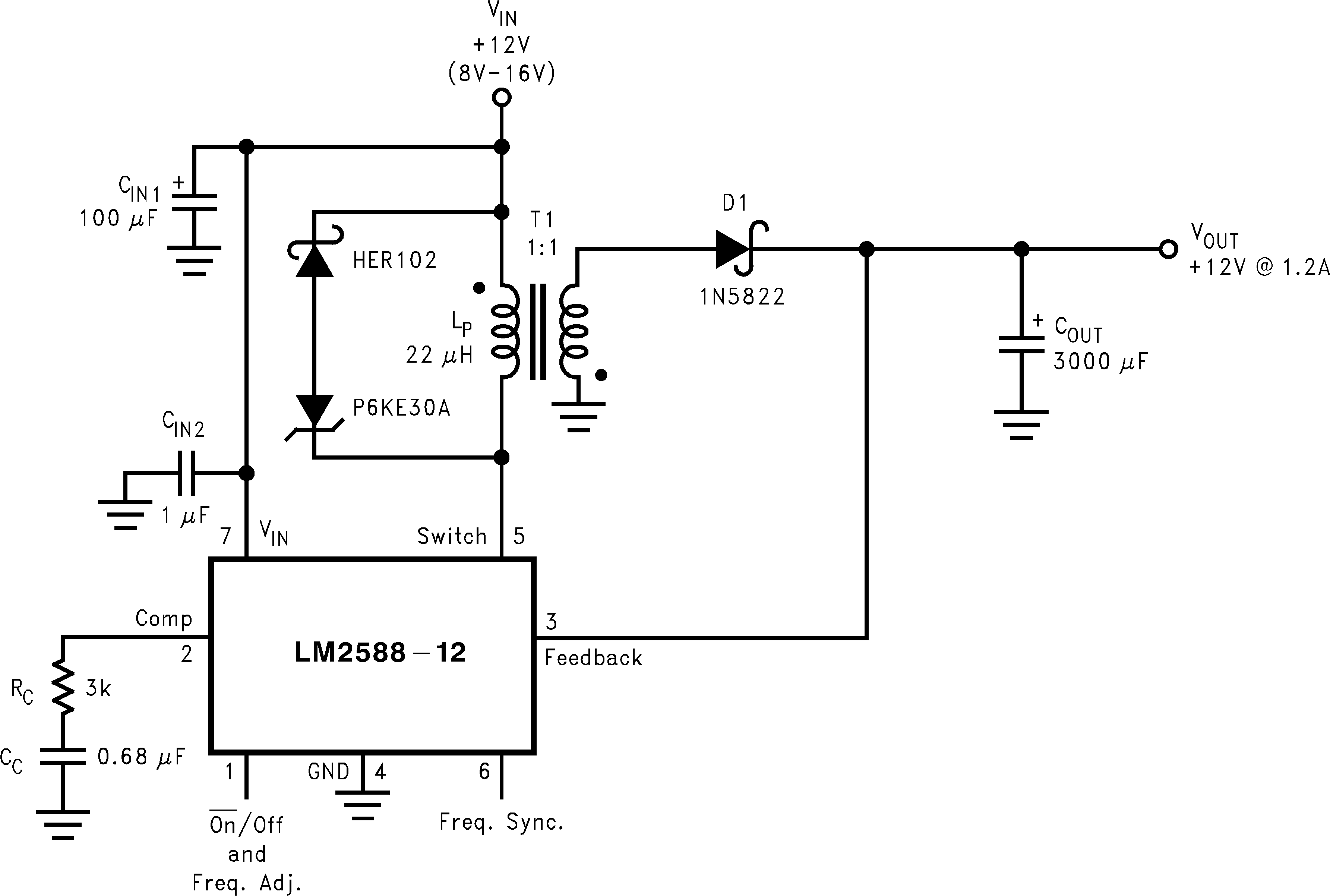

7.3.1 Flyback Regulator Operation

The operation of a flyback regulator is as follows (refer to Figure 16): when the switch is on, current flows through the primary winding of the transformer, T1, storing energy in the magnetic field of the transformer. Note that the primary and secondary windings are out of phase, so no current flows through the secondary when current flows through the primary. When the switch turns off, the magnetic field collapses, reversing the voltage polarity of the primary and secondary windings. Now rectifier D1 is forward biased and current flows through it, releasing the energy stored in the transformer. This produces voltage at the output.

The output voltage is controlled by modulating the peak switch current. This is done by feeding back a portion of the output voltage to the error amp, which amplifies the difference between the feedback voltage and a 1.23-V reference. The error amp output voltage is compared to a ramp voltage proportional to the switch current (in other words, inductor current during the switch on-time). The comparator terminates the switch on time when the two voltages are equal, thereby controlling the peak switch current to maintain a constant output voltage.