ZHCSGT2C November 2016 – August 2021 LMS3635-Q1 , LMS3655-Q1

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Device Comparison Tables

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Applications

- 9.2.1

General Application

- 9.2.1.1 Design Requirements

- 9.2.1.2 Detailed Design Procedure

- 9.2.1.3 Application Curves

- 9.2.2 Fixed 5-V Output for USB-Type Applications

- 9.2.3 Fixed 3.3-V Output

- 9.2.4 6-V Adjustable Output

- 9.2.1

General Application

- 9.3 Do's and Don't's

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

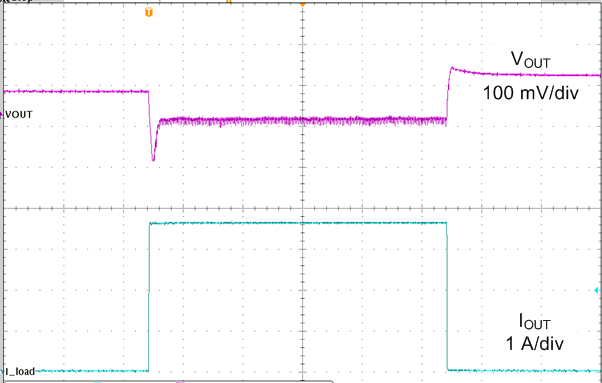

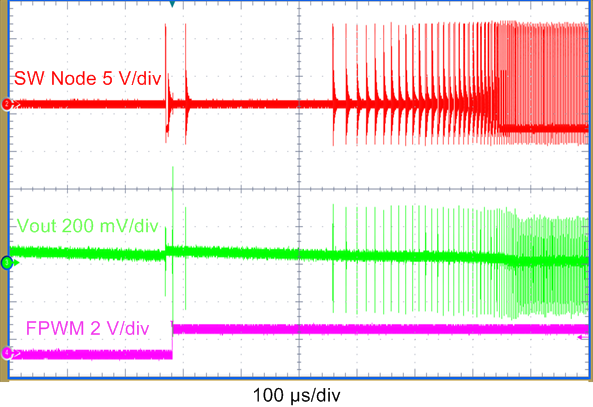

9.2.3.3 Application Curves

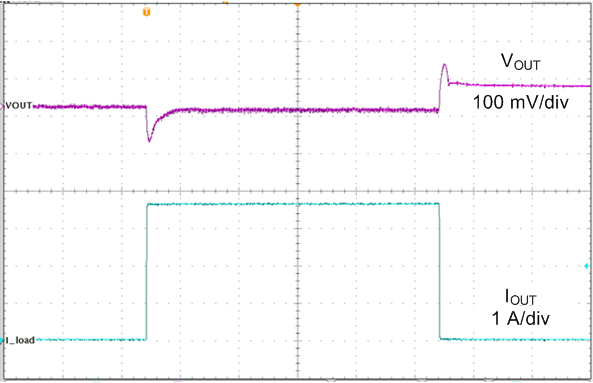

The following characteristics apply only to the circuit of Figure 9-16. These parameters are not tested and represent typical performance only. Unless otherwise stated, the following conditions apply: VIN = 12 V, TA = 25°C. For the purpose of offering more information to the designer, information for the application with FPWM pin high (FPWM mode) and FPWM pin low (AUTO mode) is included, although the schematic shows the application running specifically in AUTO mode. The mode is specified under each of the following graphs.

| VOUT = 3.3 V | AUTO |

| VOUT = 3.3 V | AUTO |

| VOUT = 3.3 V | AUTO | IOUT = 0 A |

| VOUT = 3.3 V |

| VOUT = 3.3 V | AUTO |

| AUTO | VOUT = 3.3 V | L = 10 µH, |

| COUT = 190 µF | IOUT = 0 A to 3.5 A | TR = TF = 1 µs |

| VOUT = 3.3 V | IOUT = 10 mA |

| VOUT = 3.3 V | FPWM |

| VOUT = 3.3 V | FPWM |

| VOUT = 3.3 V |

| VOUT = 3.3 V |

| VOUT = 3.3 V | L = 10 µH |

| FPWM | VOUT = 3.3 V | L = 10 µH, |

| COUT = 190 µF | IOUT = 0 A to 3.5 A | TR = TF = 1 µs |