ZHCSIH0C December 2017 – June 2021 LP87702-Q1

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 说明(续)

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Descriptions

- 8.3.1 Step-Down DC/DC Converters

- 8.3.2 Boost Converter

- 8.3.3 Spread-Spectrum Mode

- 8.3.4 Sync Clock Functionality

- 8.3.5 Power-Up

- 8.3.6 Buck and Boost Control

- 8.3.7 Enable and Disable Sequences

- 8.3.8 Window Watchdog

- 8.3.9 Device Reset Scenarios

- 8.3.10 Diagnostics and Protection Features

- 8.3.11 OTP Error Correction

- 8.3.12 Operation of GPO Signals

- 8.3.13 Digital Signal Filtering

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6 Register Maps

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

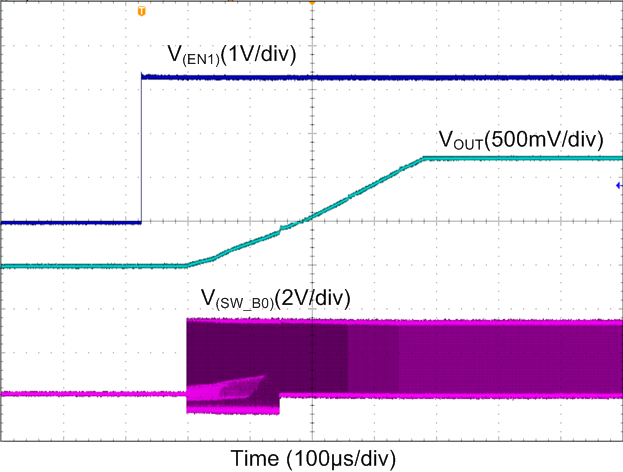

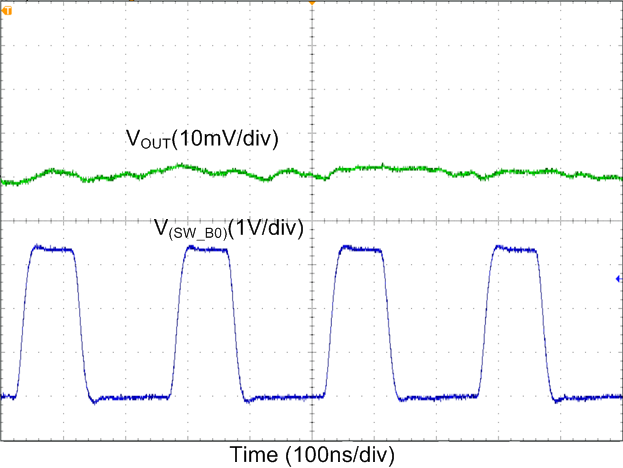

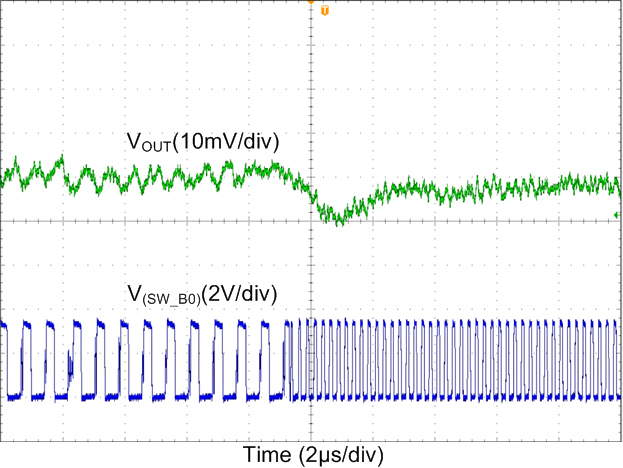

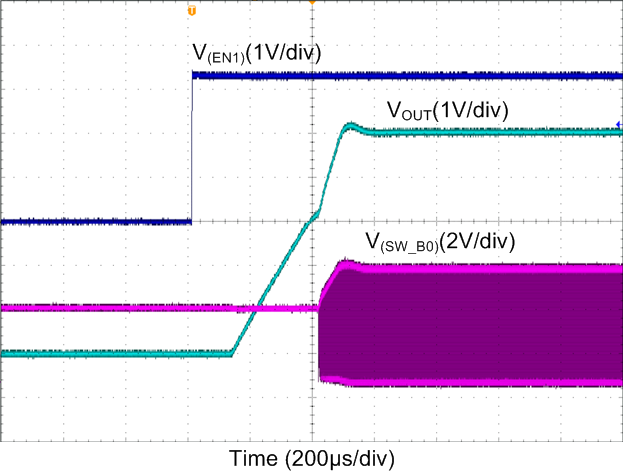

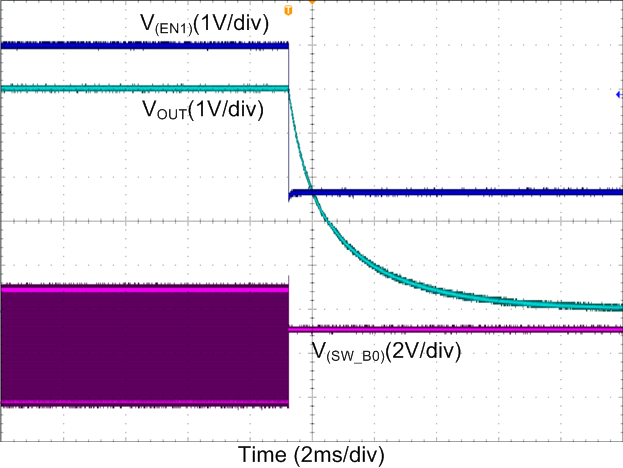

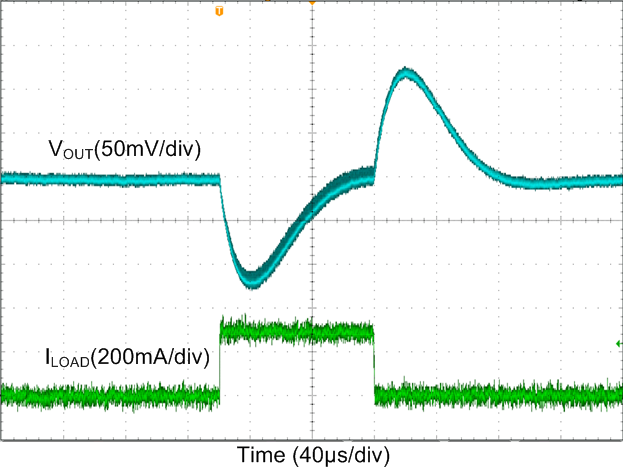

9.2.4 Application Curves

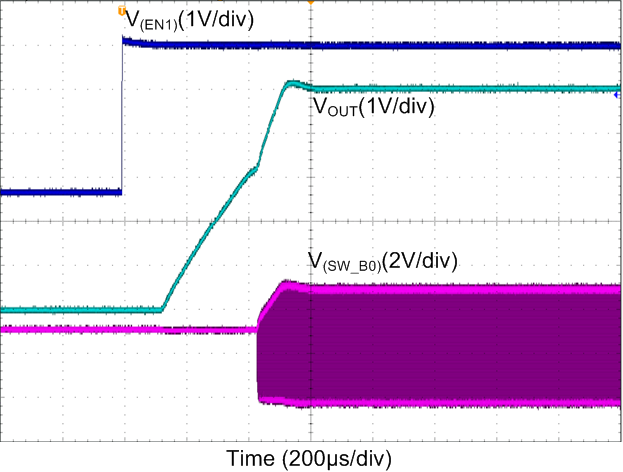

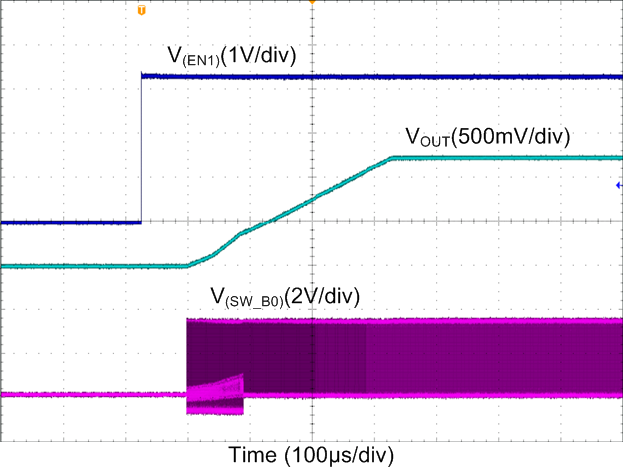

Unless otherwise specified: VIN = 3.3 V, VOUT_BUCK =

1 V, VOUT_BOOST = 5 V, TA = 25°C,

ƒSW-setting 4 MHz, L0 = L1 = 0.47 µH (TOKO DFE252012PD-R47M), L2

= 1 µH (TFM252012ALMA1R0), COUT_BUCK, CPOL_BUCK, and

COUT_BOOST = 22 µF. Measurements are done using connections

in Figure 9-1.

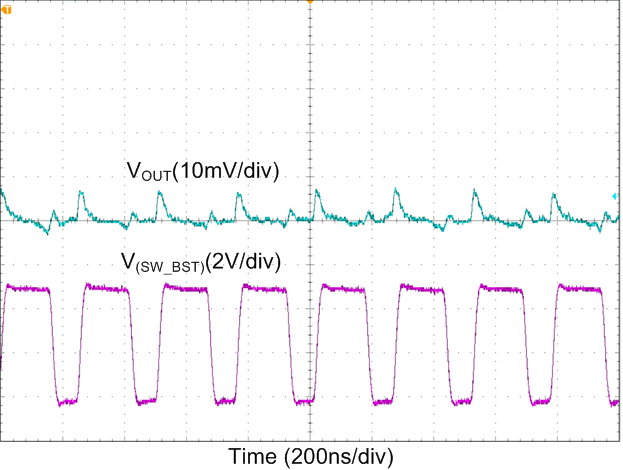

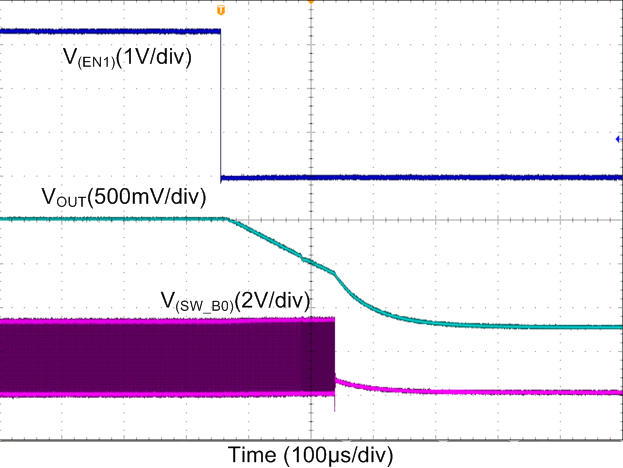

Unless otherwise specified: VIN = 3.3 V, VOUT_BUCK =

1 V, VOUT_BOOST = 5 V, TA = 25°C,

ƒSW-setting 4 MHz, L0 = L1 = 0.47 µH (TOKO DFE252012PD-R47M), L2

= 1 µH (TFM252012ALMA1R0), COUT_BUCK, CPOL_BUCK, and

COUT_BOOST = 22 µF. Measurements are done using connections

in Figure 9-1.

Figure 9-3 Buck

Efficiency in AUTO (PFM/PWM) Mode. Unless otherwise specified: VIN = 3.3 V, VOUT_BUCK =

1 V, VOUT_BOOST = 5 V, TA = 25°C,

ƒSW-setting 4 MHz, L0 = L1 = 0.47 µH (TOKO DFE252012PD-R47M), L2

= 1 µH (TFM252012ALMA1R0), COUT_BUCK, CPOL_BUCK, and

COUT_BOOST = 22 µF. Measurements are done using connections

in Figure 9-1.

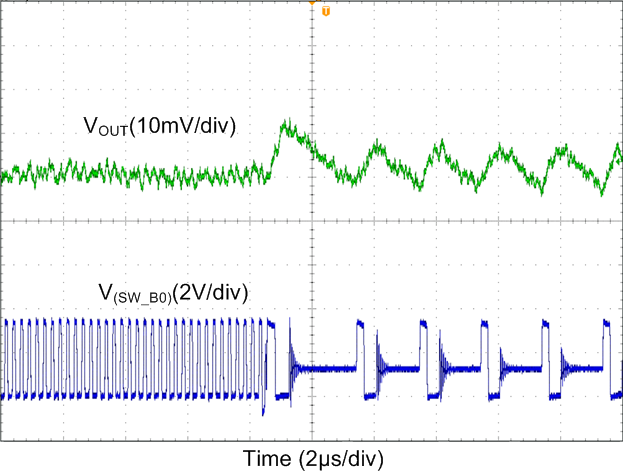

| VIN = 5 V |

| VOUT = 1 V |

| RLOAD = 1 Ω |

| VOUT = 1.2 V | IOUT = 500 mA |

| VOUT = 1.2 V |

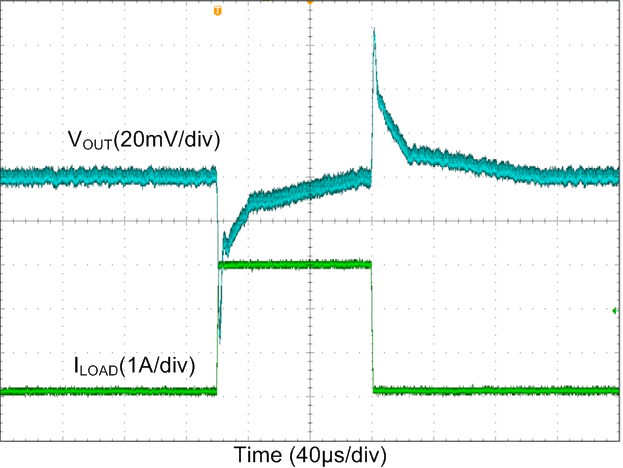

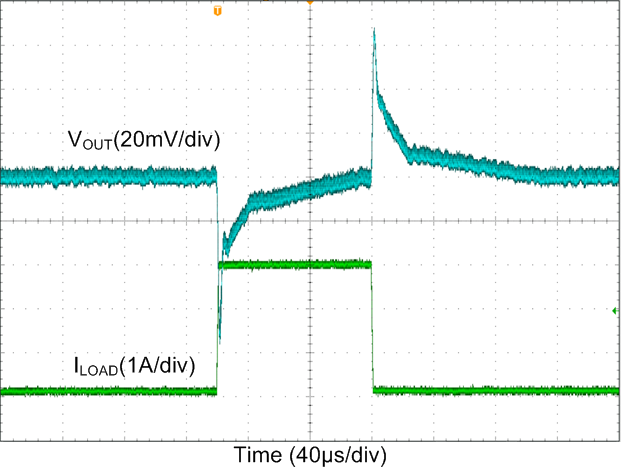

| IOUT = 0 A → 3 A → 0 A | TR = TF = 1 µs | VOUT = 1 V |

| IOUT = 0 A → 3 A → 0 A | TR = TF = 1 µs | VOUT = 1 V |

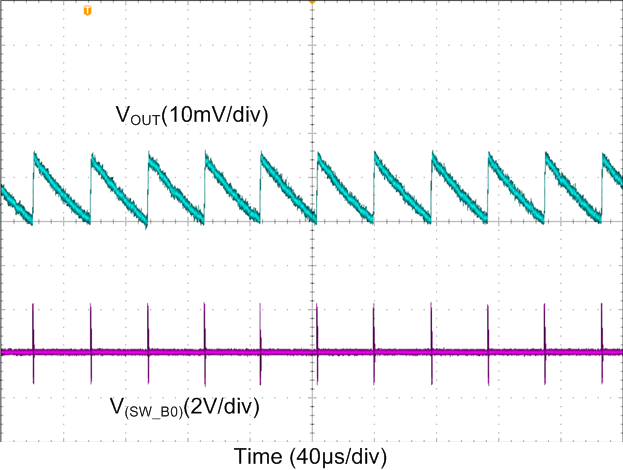

| IOUT = 0.1 A |

| RLOAD = 50 Ω |

| IOUT = 0.1 A |

| VIN = 3.3 V |

| VOUT = 1 V |

| IOUT = 0 A |

| RLOAD = 1 Ω |

| VOUT = 1.2 V | IOUT = 10 mA |

| VOUT = 1.2 V | |||

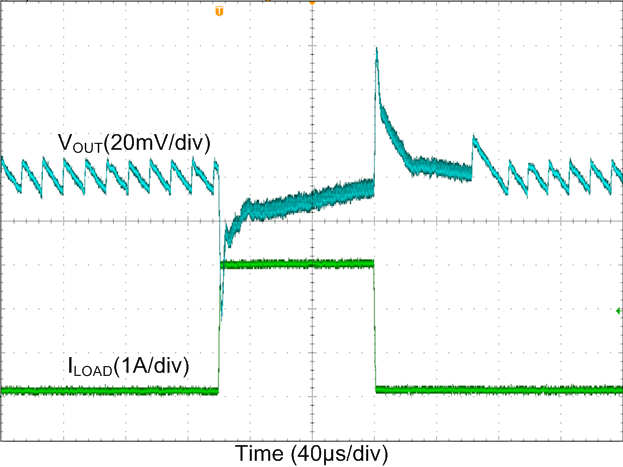

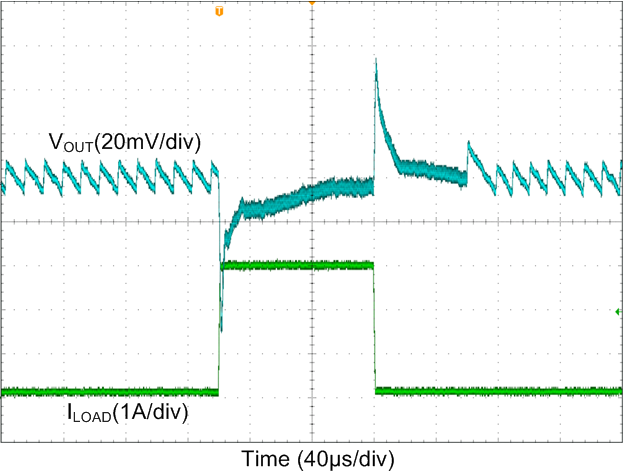

| IOUT = 0 A → 3 A → 0 A | TR = TF = 1 µs | VOUT = 1.2 V |

| VOUT = 1.2 V |

| IOUT = 0 A |

| RLOAD = 50 Ω |

| IOUT = 0 A → 0.25 A → 0 A | TR = TF = 1 µs |