SBOA615 November 2024 INA180 , INA180-Q1 , INA181 , INA181-Q1 , INA183 , INA185 , INA185-Q1 , INA186 , INA186-Q1 , INA190 , INA190-EP , INA190-Q1 , INA191 , INA199 , INA199-Q1 , INA209 , INA210 , INA210-Q1 , INA211 , INA211-Q1 , INA212 , INA212-Q1 , INA213 , INA213-Q1 , INA214 , INA214-Q1 , INA215 , INA215-Q1 , INA216 , INA2180 , INA2180-Q1 , INA2181 , INA2181-Q1 , INA219 , INA2191 , INA220 , INA220-Q1 , INA223 , INA225 , INA225-Q1 , INA226 , INA226-Q1 , INA228 , INA228-Q1 , INA229 , INA229-Q1 , INA2290 , INA230 , INA231 , INA232 , INA233 , INA234 , INA236 , INA237 , INA237-Q1 , INA238 , INA238-Q1 , INA239 , INA239-Q1 , INA240 , INA240-Q1 , INA241A , INA241A-Q1 , INA241B , INA241B-Q1 , INA250 , INA250-Q1 , INA253 , INA253-Q1 , INA254 , INA260 , INA280 , INA280-Q1 , INA281 , INA281-Q1 , INA290 , INA290-Q1 , INA293 , INA293-Q1 , INA296A , INA296A-Q1 , INA296B , INA296B-Q1 , INA300 , INA300-Q1 , INA301 , INA301-Q1 , INA302 , INA302-Q1 , INA303 , INA303-Q1 , INA310A , INA310A-Q1 , INA310B , INA310B-Q1 , INA3221 , INA3221-Q1 , INA381 , INA381-Q1 , INA4180 , INA4180-Q1 , INA4181 , INA4181-Q1 , INA4230 , INA4235 , INA4290 , INA700 , INA740A , INA740B , INA745A , INA745B , INA780A , INA780B , INA790B , INA791B , LMP8278Q-Q1 , LMP8601 , LMP8601-Q1 , LMP8602 , LMP8602-Q1 , LMP8603 , LMP8603-Q1 , LMP8640 , LMP8640-Q1 , LMP8640HV

- 1

- Abstract

- Trademarks

- 1Introduction

- 2What is ESD, EOS, and Latch Up?

- 3Risky Applications for Current Sense Amplifiers

- 4Summary

- 5References

2.2 Electrical Static Discharge

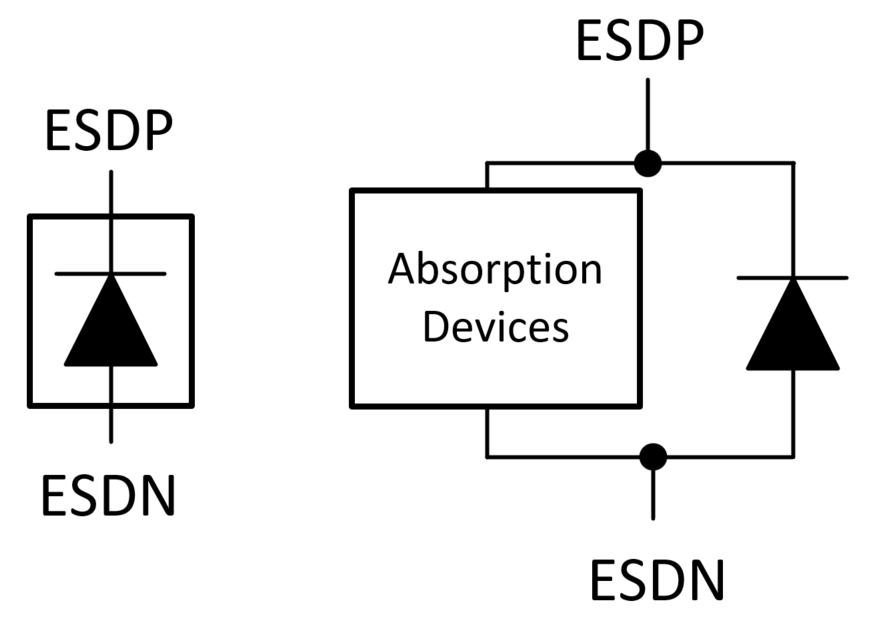

Electrical Static Discharge (ESD) events are fast high voltage events (spikes are over within hundreds of Nano-seconds) caused by the sudden discharge of static charge buildup on human and machine handlers of IC components before or after ESD events are assembled onto PCBs. CSAs (and most amplifiers in general) are protected from the high-voltage, fast edge ESD events with ESD cells. ESD cells are complex, but are essentially comprised of an absorption device and body diode.

Figure 2-1 ESD Cell

Figure 2-1 ESD CellFor a fast overvoltage event (positive or negative), an ESD cell is triggered and then the absorption device can quickly begin to sink increasing current. Once current through absorption device is high enough, the current can snap back. However, if the over voltage event lasts longer than the ESD is designed for (EOS) and there is no resistance to limit current into ESD cell, the current can increase quickly and generate excessive heat and damage the device.

Note that the body diode of the ESD cell can become forward biased when the input voltage drops somewhere below -0.3V. This is why many standard low-voltage CSAs have minimum Absolute Common-Mode Voltage (VCM) ratings of GND-0.3V.

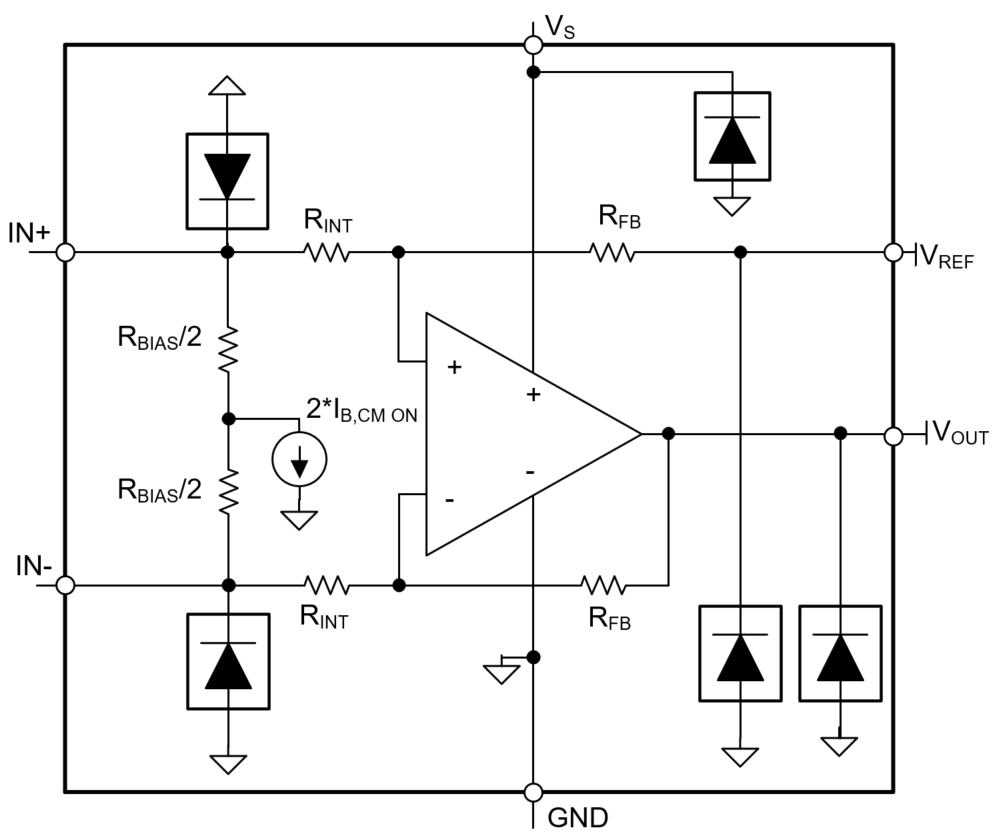

Figure 2-2 shows the general ESD topology for a CSA.

Figure 2-2 ESD Architecture Single Stage

CSA

Figure 2-2 ESD Architecture Single Stage

CSA