SLDA021B March 2014 – February 2020 AM3892 , AM3894

8.7.2 Acceptable Method: Paste on Balls

The application of solder paste directly onto the solder balls is acceptable if a small stencil cannot be fit onto the PCB, but it is not as robust as printing onto the PCB itself. It supplies less solder paste volume and is less predictable, thereby offering more opportunities for open, insufficient, or head-in-pillow solder defects.

If paste is printed on the balls, a small fixture to hold the stencil and device, like the one shown in Figure 12, should be installed on the rework station.

Figure 12. Example of Fixture for Printing Paste on BGA Balls

Figure 12. Example of Fixture for Printing Paste on BGA Balls Tests conducted using the paste on ball method with 0.23 × 0.30-mm (0.009 × 0.012") rectangular apertures produced acceptable solder joints, but, the solder paste deposits have lower volumes and are less consistent than when they are printed on the PCB pads.

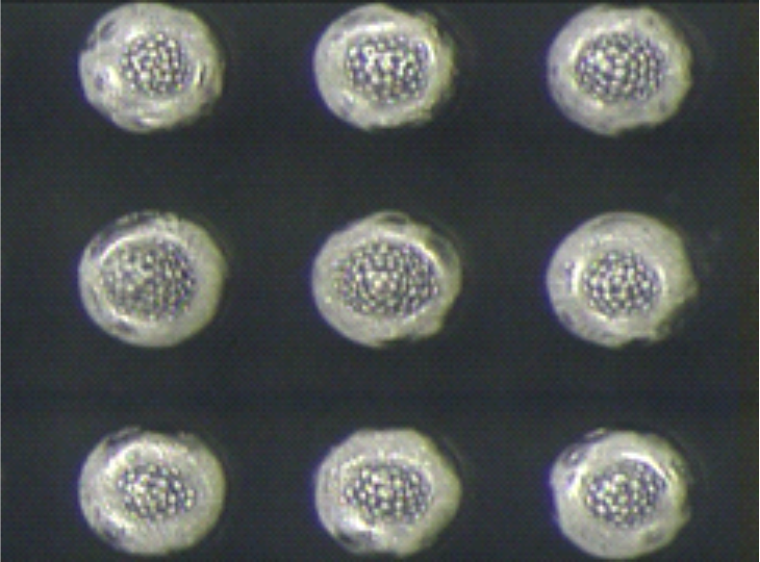

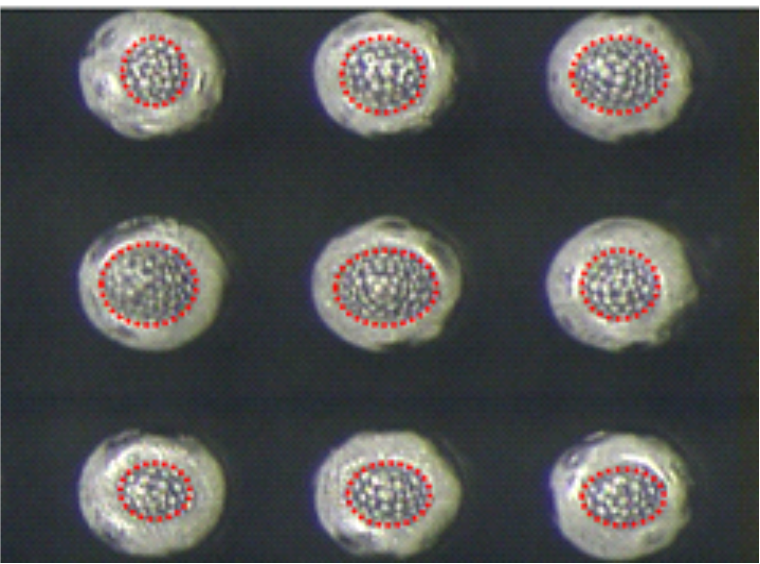

Figure 13 and Figure 14 show the same photo of typical paste-on-ball solder paste prints. The paste deposits have been outlined in red to illustrate the variation in deposit consistency that is characteristic of the paste-on-ball printing process.

Figure 13. Example of Solder Paste

Figure 13. Example of Solder Paste

Printed on BGA Balls

Figure 14. Example of Solder Paste Volume

Figure 14. Example of Solder Paste Volume

Variation on BGA Balls