SLUAAF9 September 2021 UCC28782

- Trademarks

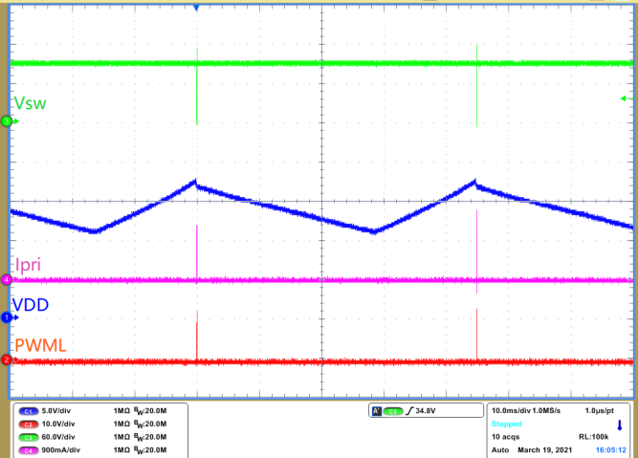

- 1 Initial Board Visual Inspection and Start-up Check

- 2 Typical System Operating Waveforms

- 3Typical System Protection Waveforms

- 4Common Issues and Solutions

- 5References

1 Initial Board Visual Inspection and Start-up Check

Before powering up the design board, the first step is to thoroughly review the design to make sure all design parameters are calculated properly. The Excel Design Calculator is a helpful tools to check the accuracy of the design. It is recommended to do a visual inspection to check for the following:

- Solder bridges

- Solder balls

- Solder skips

- Cold solder joints

- Lifted pads

After visual inspection, the user can also use a multimeter to check the solder, Multimeter locked to diode location, Red probe connected to IC ground, Black probe connected to each pin. There should be a ~0.5 V-0.7 V voltage presents on the multimeter, if not, check solder of this pin. Figure 1-1 demonstrates probing UCC28782 Pins with a digital multimeter.

Figure 1-1 Probing UCC28782 Pins with a Digital Multimeter

Figure 1-1 Probing UCC28782 Pins with a Digital MultimeterWhen the solder inspection is complete, the board can input a low voltage, next steps are input short-circuit investigation / HV start circuits operation check / CS pin fault detection and input brown in voltage (startup voltage) detection:

- Step 1: Set input voltage source to Vin=5 Vrms while limiting its current to 0.5 A, measure the input current. After a brief low inrush peak current, there should be almost zero continuous input current, if an excessive current is observed, there may be a short or abnormally low impedance in the circuit.

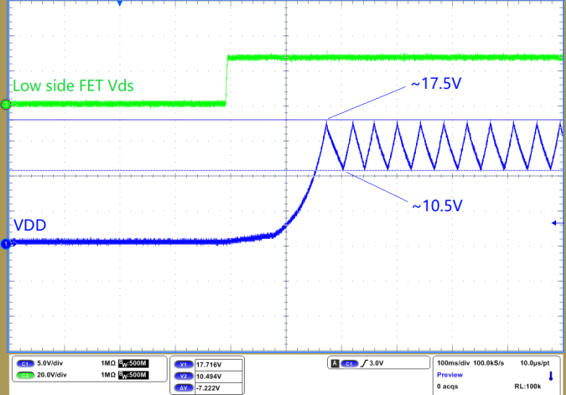

- Step 2: If zero current is observed. Move to VDD

pin to check if HV start circuits working properly, 25 Vrms voltage implied on the

input, the captured waveform of VDD as shown in Figure 1-2: If VDD voltage can be charged to ~17.5 V, it indicates the HV start circuits

working normal. if not please refer to Debugging

UCC28780 ACF Converter Start-up Issues section 7.3, Start-up

Failure Due to VDD Clamped Low.

Figure 1-2 VDD Start Up and Hiccup at

Below Brown In Voltage

Figure 1-2 VDD Start Up and Hiccup at

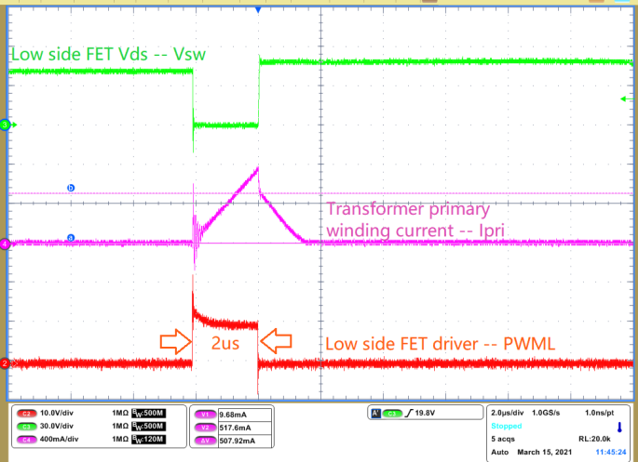

Below Brown In Voltage - Step 3: Zoom in waveform at the point when VDD

reaches to its turn on threshold (17.5 V), capture low side driver signal PWML, if

only one pulse with a width of 2us is observed, see Figure 1-4, this is the correct behavior at the input voltage which lower than start up

voltage. Please refer to Debugging

UCC28780 ACF Converter Start-up Issues section 6.1 Observation

of Zero or Only One PWML Pulse.

Figure 1-3 VDD Restart

Figure 1-3 VDD Restart Figure 1-4 CS Pin Fault Detection -

Only 1 Pulse With 2us Width

Figure 1-4 CS Pin Fault Detection -

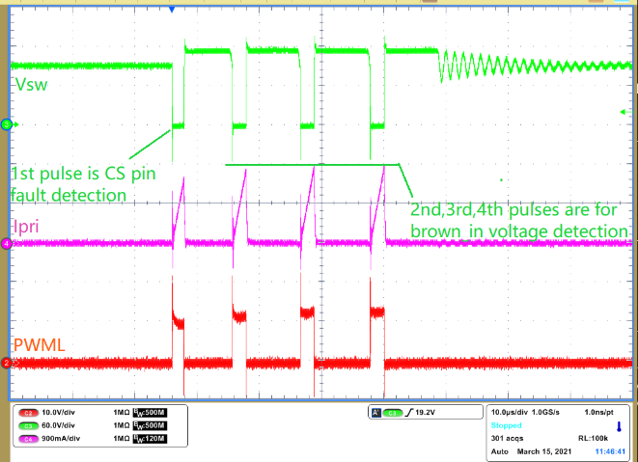

Only 1 Pulse With 2us Width - Step 4: Gradually increase input voltage until

the user can see four consecutive pulses shown in Figure 1-5. The first pulse is for CS pin fault detection, the second, third, fourth pulses

are for brown in voltage detection. When the AC input voltage is lower than brown in

voltage. The user will always see four pulses at each VDD restart cycle. Further

increasing the input voltage until it is above the brown in voltage, the board

should be powered up if there is no protection occurring.

Figure 1-5 Brown-in Voltage Detection

– 4 Consecutive Pulses

Figure 1-5 Brown-in Voltage Detection

– 4 Consecutive Pulses