SLVSE94G September 2018 – June 2024

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Device Comparison Table

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Hot Plug-In and Inrush Current Control

- 8.3.2 PGOOD and PGTH

- 8.3.3 Undervoltage Lockout (UVLO)

- 8.3.4 Overvoltage Protection (OVP)

- 8.3.5 Input Reverse Polarity Protection (B_GATE, DRV)

- 8.3.6 Reverse Current Protection

- 8.3.7 Overload and Short-Circuit Protection

- 8.3.8 Output Power Limiting, PLIM (TPS26632, TPS26633, TPS26635, TPS26636, and TPS26637 Only)

- 8.3.9 Current Monitoring Output (IMON)

- 8.3.10 FAULT Response (FLT)

- 8.3.11 IN_SYS, IN, OUT, and GND Pins

- 8.3.12 Thermal Shutdown

- 8.3.13 Low Current Shutdown Control (SHDN)

- 8.4 Device Functional Modes

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Application: Power Path Protection in a PLC System

- 9.2.1 Design Requirements

- 9.2.2 Detailed Design Procedure

- 9.2.3 Application Curves

- 9.3 System Examples

- 9.4 Dos and Do Nots

- 9.5 Power Supply Recommendations

- 9.6 Layout

- 10Device and Documentation Support

- 11Revision History

- 12Mechanical, Packaging, and Orderable Information

8.3.4 Overvoltage Protection (OVP)

The TPS2663x devices incorporate circuitry to protect the system during overvoltage conditions. The TPS26630 and TPS26631 feature an accurate ±2% adjustable overvoltage cutoff functionality. A voltage more than V(OVPR) on OVP pin turns off the internal FET and protects the downstream load. To program the OVP threshold externally, connect a resistor divider from IN_SYS supply to OVP terminal to GND as shown in the Simplified Schematic.

The TPS26630 and TPS26631 also feature a factory set 34.3-V input overvoltage cutoff V(IN_SYS_OVP) threshold with a 440-mV hysteresis. This feature can be enabled by connecting the OVP terminal directly to the GND terminal. The TPS26632, TPS26633 and TPS26636 feature an internally fixed 35-V maximum overvoltage clamp V(OVC) functionality. The TPS26632 and TPS26633 clamps the output voltage to V(OVC) when the input voltage exceeds 35 V. TPS26635 features a fixed 39-V maximum overvoltage clamp level. During the output voltage clamp operation, the power dissipation in the internal MOSFET is PD = (V(IN_SYS) – V(OVC)) × I(OUT). Excess power dissipation for a prolonged period can increase the device temperature. To avoid this increase, the internal FET is operated in overvoltage clamp for a maximum duration of tOVC(dly), 162 ms (typical). After this duration, the internal FET is turned OFF and the subsequent operation of the device depends on the MODE configuration (auto-retry or latch-off) setting as shown in Table 8-1.

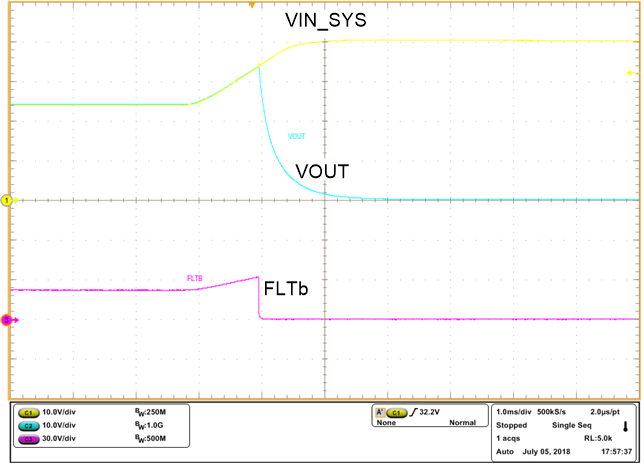

Figure 7-1 shows the turn-ON behavior when OVP pin voltage falls below V(OVPF) threshold.

Figure 8-5 illustrates the overvoltage cutoff functionality and Figure 8-6 illustrates the overvoltage clamp functionality. FLT is asserted after a delay of 617 µs (typical) after entering in overvoltage clamp mode and remains asserted until the overvoltage fault is removed.

| TPS26630 and TPS26631 | ||

| TPS26635 | RLOAD = 30 Ω, FLT connected to VOUT | |