SNOA951 June 2016 LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1

- Inductive Sensing Touch-On-Metal Buttons Design Guide

1 ToM Basics

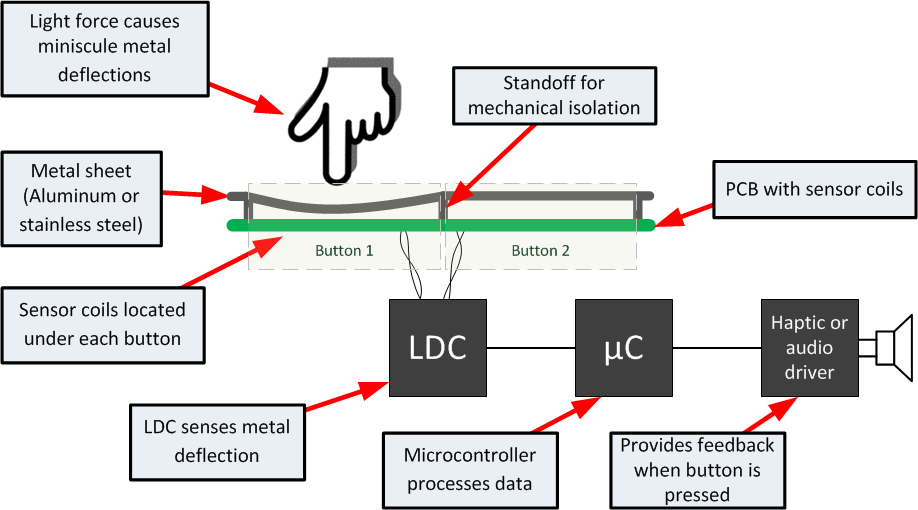

ToM buttons refers to using a flat metal surface as a button and a high resolution inductance converter such as the LDC1612 to detect the microscopic metal deflection that occurs when the button is pressed. Figure 1 shows a block diagram of a touch-on-metal solution with two buttons. When even a light force is applied to a button, the inner surface of the metal sheet will be pushed towards the PCB sensors. The metal sheet does not contact the sensors but the small amount of deflection from the press causes a shift in the sensor inductance that can be detected by the LDC and then interpreted as a button press by a microcontroller (MCU). Haptics such as a vibration, audible beep, or visual indication may also be triggered to give the user an acknowledgement of an accepted button press.

Figure 1. System Block Diagram of a Touch-On-Metal Implementation

Figure 1. System Block Diagram of a Touch-On-Metal Implementation Inductive-sensing based designs for touch-on-metal offers a completely sealed and contactless solution with a greatly simplified assembly process. In addition to being insensitive to dirt, moisture, and other contaminants, inductive touch-on-metal buttons offer a robust solution that does not use moving mechanical parts, and offers a flat surface that is easy to clean for home appliances. Unlike mechanical buttons, inductive sensing-based buttons can detect the amount of pressure on the button, allowing for adjustable sensitivity or the ability to program the button for different functions depending on the amount of pressure applied. In addition to working with grounded and ungrounded button panels, inductive sensing also provides excellent immunity towards EMI sources due to a narrow-band resonant sensing approach.