SPRUJF1 November 2024 AM2612

ADVANCE INFORMATION

- 1

- Description

- Key Features

- 1LaunchPad Module Overview

-

2Hardware Description

- 3.1 Board Setup

- 3.2 Functional Block Diagram

- 3.3 GPIO Mapping

- 3.4 Reset

- 3.5 Clock

- 3.6 Memory Interfaces

- 3.7 Ethernet Interface

- 3.8 I2C

- 3.9 Industrial Application LEDs

- 3.10 SPI

- 3.11 UART

- 3.12 MCAN

- 3.13 FSI

- 3.14 JTAG

- 3.15 TIVA and Test Automation Pin Mapping

- 3.16 LIN

- 3.17 ADC and DAC

- 3.18 EQEP and SDFM

- 3.19 EPWM

- 3.20 USB

- 3.21 BoosterPack Headers

- 3Known Issues and modifications done on LP-AM261 RevE1

- 4Additional Information

- 5References

- 6Revision History

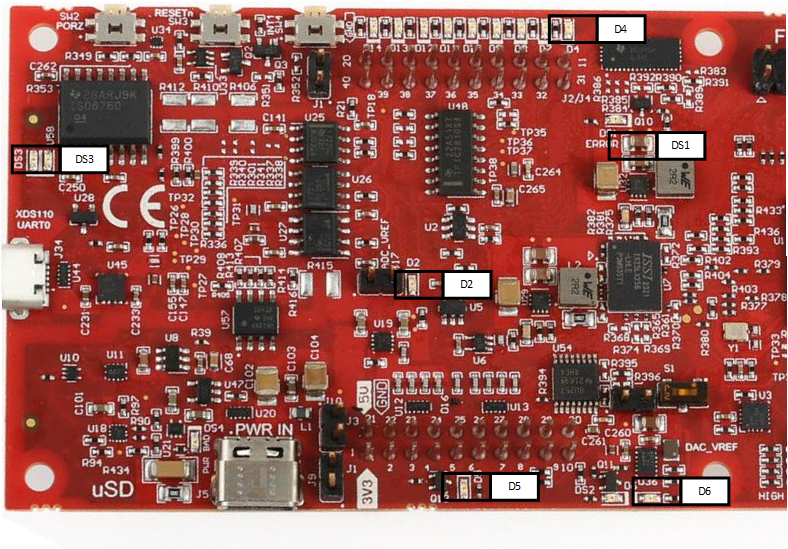

2.1.1.2 Power Status LEDs

Multiple power-indication LEDs are provided onboard to indicate to users the output status of major supplies. The LEDs indicate power across various domains.

Table 2-3 Power Status LEDs

| Name | Default Status | Operation | Function |

|---|---|---|---|

| D7 | ON | VSYS_5V0 | Power indicator for supply 5V voltage |

| D14 | ON | VSYS_3V3 | Power indicator for generated 3.3V voltage |

| D16 | ON | VSYS_2V5 | Power indicator for generated 2.5V voltage |

| D12 | ON | VDD_1V2 | Power indicator for generated 1.2V power-good voltage |

| D15 | ON | VSYS_1V8 | Power indicator for generated 1.8V voltage |

| D13 | OFF | WARMRSTN | Power indication for WARMRSTN |

| DS2 | OFF | SAFETY_ERROR | Power error indication for SAFETY_ERROR |

| D1 | OFF | XDS_PROGSTAZ1 | LED will glow after micro-B connection is made |

| DS1 | OFF | XDS_PROGSTAZ2 | LED will glow to indicate communication over JTAG |

Note: DS2 LED that correspond to SAFETY_ERROR is

always ON.

Figure 2-3 Power Status LEDs

Figure 2-3 Power Status LEDs