SSZT080 april 2022 LMG3522R030-Q1

The adoption of gallium nitride (GaN) field-effect transistor (FET) is rapidly increasing, given its ability to improve efficiency and shrink the size of power supplies. But before investing in the technology, you may still be asking yourself whether GaN is reliable. It strikes me that no one asks whether silicon is reliable. After all, there are still new silicon products coming out all the time, and power-supply designers also care about the reliability of silicon power devices.

The truth is, the GaN industry has invested considerable effort and time on reliability.

For silicon, the reliability question is phrased differently – "Did it pass qualification?" Although GaN parts also pass silicon qualification, power-supply manufacturers are not convinced that the silicon methodology assures reliable GaN FETs. This is a valid point, since not all silicon device tests are applicable to GaN, and traditional silicon qualification itself does not include stress tests for the actual switching conditions of power-supply usage. The JEDEC JC-70 Wide Bandgap Power Electronic Conversion Semiconductors committee has released several GaN-specific guidelines to address the deficiencies.

| Understanding GaN Product Reliability | |

|

Read the technical white paper, "Achieving GaN Products with Lifetime Reliability," to learn more about our GaN reliability testing. |

How Do You Validate GaN’s Reliability?

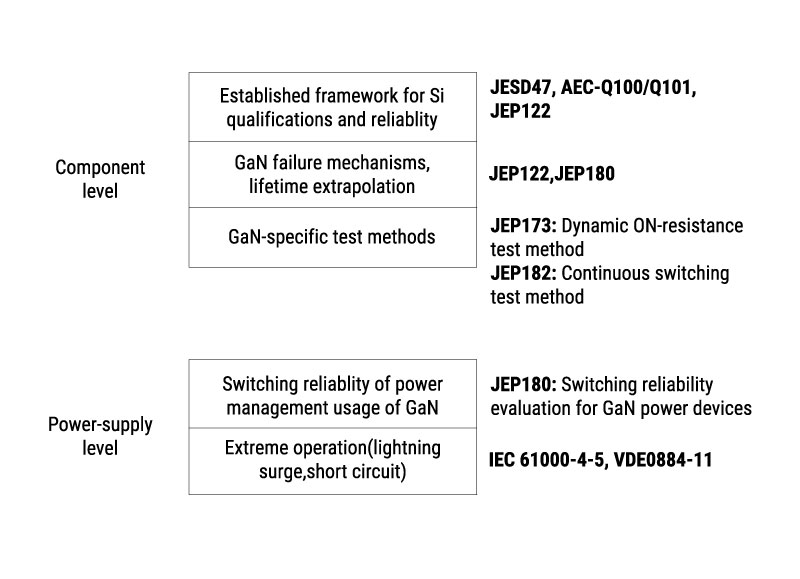

GaN FET reliability is validated through the established silicon methodology, combined with reliability procedures and test methods designed to address GaN-specific failure modes such as an increase in the dynamic drain-to-source on-resistance (RDS(ON)). Figure 1 lists the steps to achieving reliable GaN products.

Figure 1 GaN-specific Guidelines for

Reliability in Conjunction with Established Silicon Standards

Figure 1 GaN-specific Guidelines for

Reliability in Conjunction with Established Silicon StandardsWe have categorized testing into component- and power-supply-level blocks, with relevant standards and guidelines for each block. At the component level, TI runs bias, temperature and humidity stress tests according to the traditional silicon standards, uses GaN-specific test methods and determines lifetimes by applying accelerated stress until device failure. At the power-supply level, parts are run under stringent operating conditions for the relevant application. TI also validates robustness for extreme operating conditions from occasional events.

The Reliability of GaN FETs in Your Application

The JEDEC JEP180 guideline provides a common approach for assuring the reliability of GaN products in power-conversion applications. To meet JEP180, a GaN manufacturer must demonstrate that its product has the required switching lifetime for the relevant stress and runs reliably under stringent operating conditions in a power supply. The former demonstration uses switching accelerated lifetime testing (SALT) to stress devices to failure, and the latter uses dynamic high-temperature operating life (DHTOL) testing.

Devices are also subject to extreme operating conditions in the real world – events such as short circuits and power-line surges. TI GaN products such as the LMG3522R030-Q1 have built-in short-circuit protection. Surge robustness across a range of applications entails the consideration of both hard- and soft-switching stresses. GaN FETs handle power line surges differently from silicon FETs. Rather than enter avalanche breakdown, GaN FETs switch through surge strikes as a result of their overvoltage ability. An overvoltage ability can also improve system reliability because avalanching FETs cannot absorb much avalanche energy, so the protection circuitry must absorb most of the surge. The degradation of surge-absorption components with aging subjects silicon FETs to higher levels of avalanche, which can cause failures. In contrast, a GaN FET will continue switching.

Are TI GaN Products Reliable?

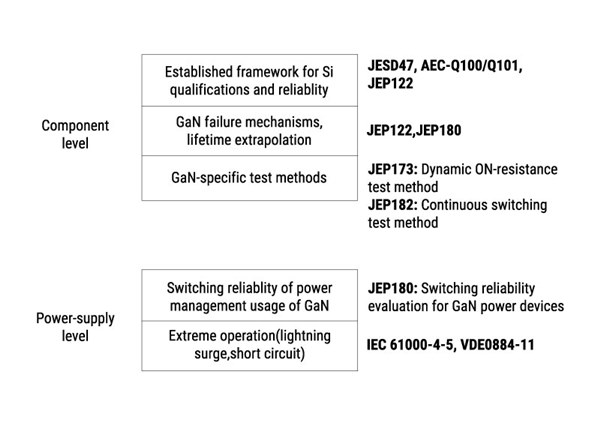

TI qualifies its GaN products according to the methodology shown in Figure 1. Figure 2 summarizes the outcomes, showing the results from both component- and power-supply-level blocks.

Figure 2 GaN FET Reliability Is

Validated by GaN Specific Guidelines Using the Methodology Shown in

Figure 1

.

Figure 2 GaN FET Reliability Is

Validated by GaN Specific Guidelines Using the Methodology Shown in

Figure 1

.At the component level, TI GaN passes traditional silicon qualification and has high reliability for GaN-specific failure mechanisms. TI has engineered and validated high reliability for time-dependent breakdown (TDB), charge trapping and hot-electron wearout failure mechanisms, and demonstrated that dynamic RDS(ON) is stable with aging.

To determine the component switching lifetime, our SALT validation applies accelerated hard-switching stress, as described in "A Generalized Approach to Determine the Switching Lifetime of a GaN FET." The TI model uses switching waveforms to directly calculate the switching lifetime, and shows that a TI GaN FET will not fail from hard-switching stresses throughout the product’s lifetime.

To validate power-supply level reliability, we ran DHTOL testing on 64 TI GaN parts under stringent power-supply usage conditions. Devices showed stable efficiency with no hard failure, demonstrating reliable operation for all modes of power-supply operation: hard and soft switching, third-quadrant operation, hard commutation (reverse recovery), Miller shoot-through with high slew rates, and reliable interaction with the driver and other system components. TI has additionally validated surge robustness by applying surge strikes to devices running in power supplies under both hard- and soft-switching operation, and showed that TI GaN FETs can effectively switch through bus voltage surges as high as 720 V, which provides significant margin. Learn more about this testing in "A New Approach to Validate GaN FET Reliability to Power-Line Surges Under Use Conditions."

Conclusion

The GaN industry has built a methodology to assure the reliability of GaN products, so the question is not "Is GaN reliable?", but "How do you validate GaN’s reliability?" TI GaN devices are reliable at both the component level and in real-world applications. They have passed both silicon qualification standards and GaN industry guidelines. In particular, TI GaN products pass JEP180, demonstrating that they are reliable for power-supply usage.

Additional Resources

- Browse TI’s line of GaN products.

- Learn about the benefits of GaN technology.