SSZT199 january 2021 HDC2010 , HDC2021 , HDC2022 , HDC2080 , HDC3022 , TMP1826 , TMP61 , TMP63 , TMP64

When designing for increased efficiency in heating, ventilation and air-conditioning (HVAC) systems, sensor accuracy and consistency have a significant effect. A system’s ability to accurately sense and measure temperature and humidity levels of inside and outside air sensors, damper controls, thermostats and fans minimizes system run time because the system can use more data to make better decisions. Along with proper HVAC implementation and maintenance, real-time control of HVAC system components and sensor choice can save consumers as much as 25%.

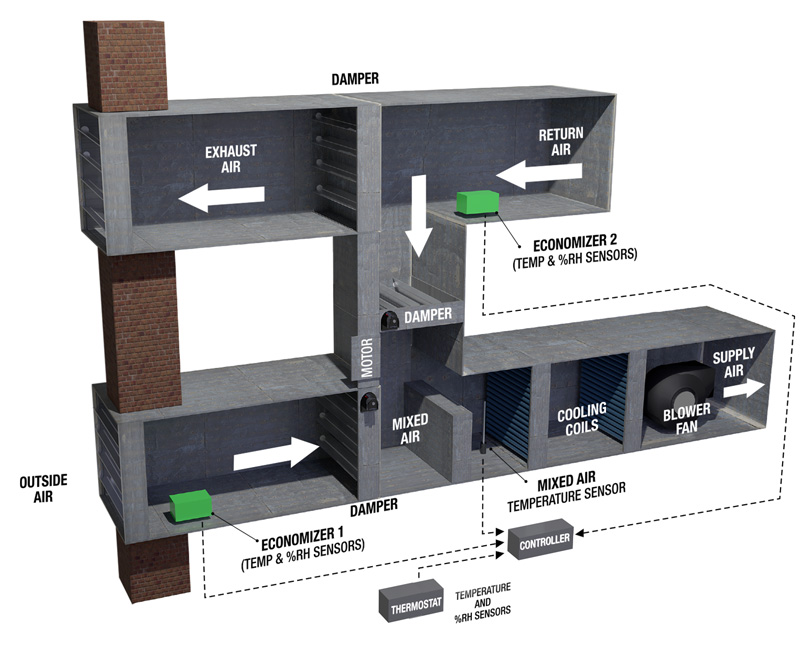

When designing HVAC systems like the one shown in Figure 1, sensor accuracy, repeatability and overall reliability are extremely important.

Figure 1 A commercial or residential

HVAC system

Figure 1 A commercial or residential

HVAC systemHVAC operation and efficiency

HVAC systems without humidity sensors will not provide the cooling necessary to dehumidify the air before it enters the building. Using a single enthalpy economizer instead of dry-bulb temperature lowers cooling costs in most climates. And while these systems are effective and provide improvement over temperature-only systems, a second combined sensor module in the system adds another measurement location for data, and thus an opportunity to increase system efficiency.

Why accuracy and consistency matter

Technological advancements have made it possible to integrate sensing elements with low drift and high accuracy. The HDC3022 is a factory-calibrated integrated humidity and temperature sensor with a typical relative humidity of 1.5%; a respective 0.2% relative humidity long-term drift; and a hydrophobic IP67 filter that protects against water and dust and is less susceptible to condensation than a device without a filter. These humidity sensors have an integrated temperature sensor with better than 0.4°C accuracy

Even with such high-performance sensors, you need to consider impacts to accuracy beyond the sensor. Placing printed circuit boards in an enclosure for protection will require compensation to account for differences between that enclosed environment and what the user may experience.

These same concepts apply to independent temperature measurements. A compressor discharge temperature could be 110°C and rise as high as 135°C or 140°C when malfunctioning. A typical temperature sensor with an accuracy of ±3°C to ±5°C and a long-term drift of ±5°C to ±10°C would leave 15°C of design margin for the compressor. As the compressor ages, this sensor drift limits compressor efficiency by forcing it to shut down prematurely.

A linear thermistor such as the TMP61 offers inherently low long-term drift and is capable of 150°C, at a cost similar to NTC thermistors. Its linearity enables improved accuracy with software techniques such as analog-to-digital oversampling to increase resolution and reduce the effect of noise. Its high accuracy and low long-term drift enable the compressor to reduce protection margins, allowing the system to shut down less often to prevent overheating, which leads to greater efficiency. Alternatively, for the most design simplicity, system designers may consider the TMP18x digital temperature sensor, which offers ultra-high accuracy out of the box, without the sacrifice of extra wiring due to a special mode requiring only 1-wire data communication and a ground wire.

Conclusion

- Read the application report, “Compensating Temperature and Humidity Sensors in HVAC Systems.”

- Read the application report, “TMP6x Oversampling.”