SSZT220 november 2020 LMG3522R030-Q1 , TMS320F280049C , TMS320F28388D

Intent on accelerating electric vehicle (EV) adoption by addressing top consumer concerns such as driving range, charge time and affordability, automakers worldwide are demanding increased battery capacity and faster charging capability, with little to no increase in size, weight or component cost.

The EV onboard charger (OBC), which allows consumers to recharge the battery directly from an AC main at home or at public or commercial outlets, is undergoing rapid changes. The need to increase charging rates has led to an increase in power levels from 3.6 kW to 22 kW, but at the same time, the OBC must fit inside the existing mechanical envelope and carried around by the car at all times without impacting driving ranges. Finally, there’s a movement to increase OBC power densities from <2 kW/L today to >4 kW/L.

The impact of switching frequency

The OBC is essentially a switch-mode power converter. Passive components such as transformers, inductors, filters and capacitors, along with heat sinks, constitute the bulk of its weight and size. Increasing the switching frequency means smaller passive components. A higher switching frequency, however, causes higher power dissipation in switching elements like power metal-oxide semiconductors (MOSFETs) and insulated gate bipolar transistors.

Reducing size requires a further reduction in power losses to maintain the same component temperatures, as there is a smaller surface area available now to extract heat. This higher power density demands a simultaneous increase in switching frequency as well as efficiency. And therein lies the challenge, which silicon-based power devices struggle to deliver.

Increasing the switching speed (how fast the voltages and currents change between the terminals of the device) will fundamentally reduce the switching energy losses. This is necessary, or else the practical maximum frequency is limited. Power devices with lower parasitic capacitance between their terminals – that are designed carefully in low-inductance circuit-path arrangements – offer a path forward.

Going beyond silicon

Power devices built using wide band-gap semiconductors such as gallium nitride (GaN) and silicon carbide (SiC) offer dramatically lower capacitance for a comparable on-resistance and breakdown voltage by virtue of their device physics. Higher critical electric fields for breakdown (10 times for GaN vs. silicon) and higher electron mobility (>33% for GaN vs. silicon) effectively enable a lower on-resistance and lower capacitance simultaneously. As a result, GaN and SiC FETs are inherently capable of operating at higher switching speeds with lower losses than silicon.

The advantages of GaN are particularly striking:

- GaN’s low gate capacitance enables faster turnon and turnoff during hard switching, reducing crossover power losses. GaN’s gate charge figure of merit is 1 nC-Ω.

- GaN’s low output capacitance enables rapid drain-to-source transitions during soft switching, especially with low load (magnetizing) currents. A typical GaN FET, for instance, has an output charge figure of merit of 5 nC-Ω compared to silicon at 25 nC-Ω. This enables designers to use small dead times and low magnetizing currents, which are necessary to increase the frequency and reduce circulating power losses.

- Unlike silicon and SiC power MOSFETs, a GaN transistor has no body diode inherently present in its structure, and therefore no reverse-recovery losses. This makes new high-efficiency architectures like totem-pole bridgeless power-factor correction practical at multiple kilowatts, previously impossible with silicon devices.

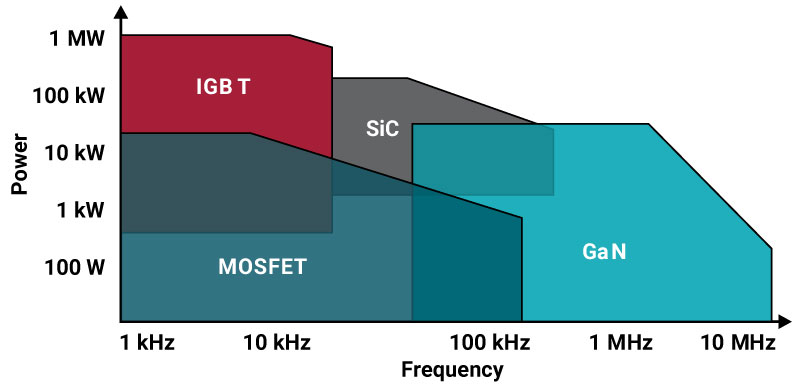

All of these advantages enable designers to achieve high efficiency at much higher switching frequencies with GaN, as illustrated in Figure 1. GaN FETs, rated to 650 V, enable applications up to 10 kW like server AC/DC power supplies, EV high-voltage DC/DC converters and OBCs (with parallel stacking to reach 22 kW). SiC devices, available up to 1.2 kV with high-current-carrying capabilities, are a good fit for EV traction inverters and large three-phase grid converters.

Figure 1 GaN surpasses all technologies

in enabling very high-frequency applications

Figure 1 GaN surpasses all technologies

in enabling very high-frequency applicationsDesign challenges with high frequency

The typical 10-ns rise and fall times when switching several hundred volts require careful design to avoid parasitic stray inductance effects. Common-source and gate-loop inductance between the FET and driver play these critical roles:

- Common source inductance limits drain-to-source transient voltages (dV/dt) and transient currents (dI/dt), slowing down switching speeds, and increasing overlap losses during hard switching and transition times during soft switching.

- Gate-loop inductance limits gate-current dI/dt, reducing switching speeds and increasing overlap losses during hard switching. Other negative effects include increasing susceptibility to Miller turnon, causing a risk of additional power losses, and introducing a design challenge to minimize gate insulator voltage overstress, which reduces reliability if not mitigated properly.

As a result, engineers may need to resort to ferrite beads and damping resistors, but these reduce switching speeds and go against the goal to increase frequency. While GaN and SiC devices are intrinsically adaptable for high-frequency operation, extracting their full benefit still means overcoming system-level design challenges. A cleverly engineered product that takes into account ease of use, robustness and design flexibility will accelerate technology adoption.

GaN FET with integrated driver, protection, reporting and power management

Fully integrated, 650-V automotive GaN FETs from Texas Instruments aim to deliver the high-efficiency, high-frequency switching benefits of GaN without the associated design and component-selection drawbacks. The integration of a GaN FET and driver in close proximity within a low-inductance quad flat no-lead (QFN) package significantly reduces parasitic gate-loop inductances, eliminating worry about gate overstress and parasitic Miller turnon, while very low common-source inductance enables fast switching, reducing losses.

The LMG3522R030-Q1, combined with the advanced control features in the C2000™ real-time microcontrollers, such as the TMS320F2838x or the TMS320F28004x, enables switching frequencies greater than 1 MHz in power converters – reducing magnetics size by 59% versus existing silicon and SiC solutions.

Demonstrated drain-to-source slew rates of >100 V/ns make it possible to reduce switching losses by 67% over discrete FETs, while its adjustability between 30 V/ns and 150 V/ns enables trade-offs between efficiency and electromagnetic interference, reducing downstream product design risk. Integrated current protections offer robustness, while new feature additions include digital pulse-width modulation temperature reporting for active power management, state-of-health monitoring and ideal diode mode, as offered in the LMG3525R030-Q1, which eliminates the need for adaptive dead-time control. A 12-mm-by-12-mm top-side cooled QFN package also enables enhanced thermal management.

With more than 40 million device reliability hours and a failure-in-time rate for 10-year lifetimes <1, TI GaN devices offer the ruggedness that automakers expect. Manufactured on widely available silicon substrates and using existing process nodes in 100% internal manufacturing facilities, TI GaN delivers definitive supply-chain and cost advantages, unlike other technologies built on SiC or sapphire substrates. Visit TI GaN online for more information about automotive GaN FETs.