SSZT284 july 2020 DRV8210 , DRV8210P , DRV8837 , DRV8837C , DRV8847 , DRV8870 , DRV8871 , DRV8873 , DRV8874 , DRV8876

As the global population grows, so does the risk for carrying and transferring germs throughout our homes, hospitals, schools and places of work. Smart sanitation products such as automatic paper towel dispensers, soap dispensers, trash cans, and smart toilets and faucets can reduce the spread of germs in common areas.

It is possible to automate every movement or valve adjustment in smart sanitation products with an electric motor or solenoid, which enables hands-free operation and reduces the potential spreading of germs by contact. Brushed-DC motors and latching solenoids are popular in these products because of their low cost and ease of design. Engineers face many challenges when designing for these applications, however, related to:

- Position and speed control

- Stall detection

- System size

- Protection

- Battery life

In this article, we will look at how our brushed-DC motor and H-bridge drivers help address these design challenges.

Position and speed control

It is very helpful to be able to control the position and speed of a brushed-DC motor in smart sanitation products. For example, a paper towel dispenser needs to dispense a specific portion from the roll in order to not waste paper, while still providing a sufficient amount to users. In order to accomplish this, the system needs some form of feedback from the motor to know where the load is.

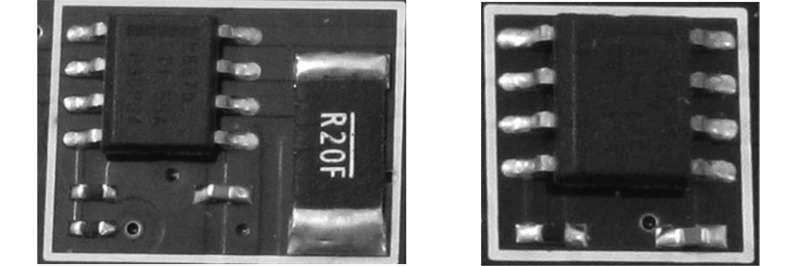

Figure 1 The DRV8870 with an external shunt resistor vs. the DRV8871 with integrated current sensing

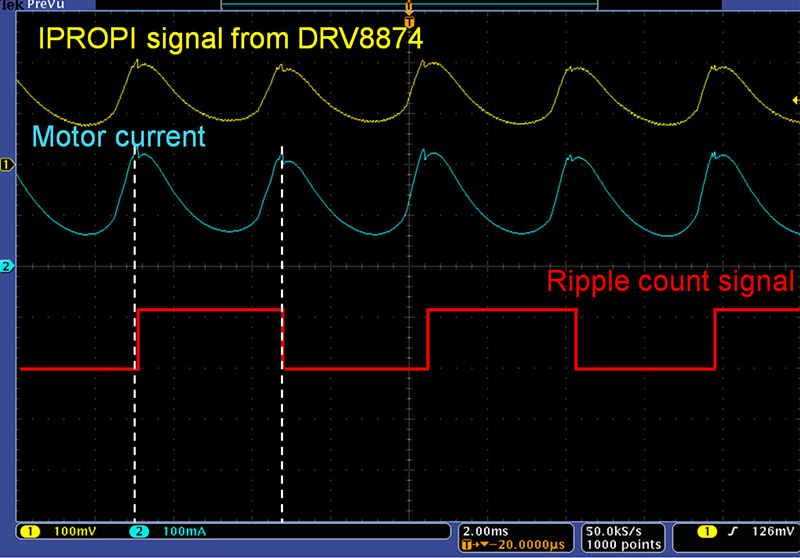

Figure 1 The DRV8870 with an external shunt resistor vs. the DRV8871 with integrated current sensingIt’s also possible to leverage the motor current for sensorless position and speed detection, commonly referred to as ripple counting. As illustrated in Figure 2, ripples in the current are formed by the brushes in the motor making contact with the commutator during each rotation. The basic principle of ripple counting is to count the number of ripples in the current, which translates into rotations and thus the relative speed and position.

Figure 2 The IPROPI current feedback signal with ripples from brushed-DC motor commutation

Figure 2 The IPROPI current feedback signal with ripples from brushed-DC motor commutationStall detection

Now that I’ve shared a technique for monitoring speed and position, let’s discuss an effective way to detect end-positions or jams in motor movement, also known as stall events.

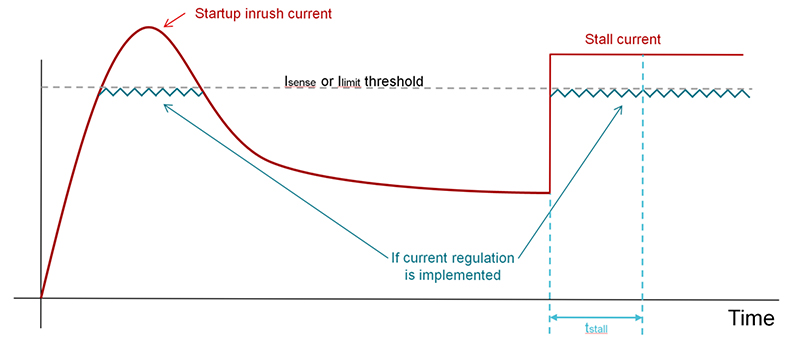

Figure 3 Typical brushed-DC motor profile for systems with possible stall events

Figure 3 Typical brushed-DC motor profile for systems with possible stall eventsUsing the IPROPI current-sense output, and the current-limit control on the DRV8873, DRV8874 and DRV8876, the microcontroller can sense these different current regions, detect the stall condition and stop driving the motor – saving energy and power without the need for any other external components.

Fitting motors and solenoids into small form factors

While many restrooms have automated systems, they still need to have an aesthetically pleasing form factor, or even be hidden from sight. This typically means that the system needs to be small, which does not leave much room for electronics.

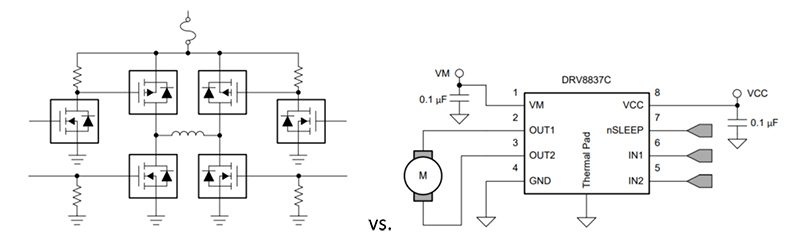

Figure 4 Discrete H-bridge circuit (a); integrated motor driver H-bridge with the DRV8837C (b)

Figure 4 Discrete H-bridge circuit (a); integrated motor driver H-bridge with the DRV8837C (b)Automatic faucets often have two valves for mixing cold and hot water and can require two solenoids or brushed-DC motors, which in turn requires two H-bridges, taking up more space on the board. Devices like the DRV8847 are a good solution to integrate multiple motor drive systems into a single integrated circuit.

Battery-powered smart sanitation products and general design considerations

Since many smart sanitation products are battery powered, such as flushometers, and soap or paper towel dispensers, reducing the power consumption of the motor driver to extend battery life is crucial. Devices such as the DRV8837 will typically draw just 35 nA of current while waiting for a wake-up command from the microcontroller.

Additional resources

- Check out our brushed-DC motor driver portfolio to find the right motor driver for your smart sanitation system.