SSZT353 january 2020 CC2652RB

Wouldn’t it be nice to know the condition of parts in your car exposed to mechanical vibrations or shock from the engine, or to get information about the status of systems operating under severe mechanical vibration conditions in an automated factory? With this information, you could perform predictive maintenance and replace fatigued parts before they fail completely, substantially reducing car problems or factory downtime. Check out this video demo of our crystal-less wireless TI BAW technology being put to the test and learn more in the technical article below.

Connect: Crystal-less wireless MCU demo in mechanical shock and vibration environments

How BAW technology resists mechanical shock and vibration

One of the most critical performance metrics for any wireless device is to maintain a link between the transmitter and receiver and prevent data loss. Without the need for a crystal, BAW technology provides significant performance benefits for IoT products operating in harsh environments. Because BAW technology ensures stable data transmission, data syncing over wired and wireless signals is more precise and makes continuous transmission possible, which means that data can be processed quickly and seamlessly to maximize efficiency.

Evaluating BAW technology with high industry standards

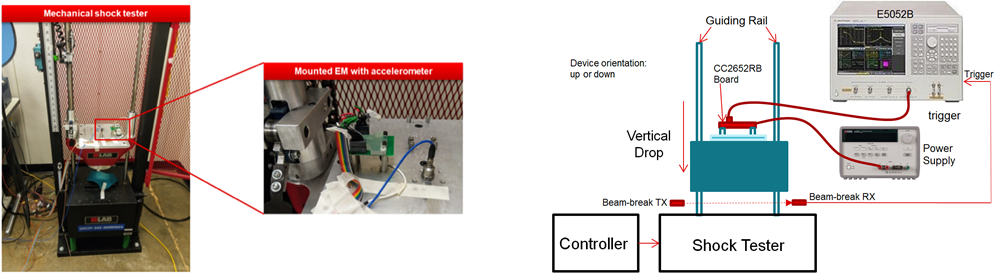

Figure 1 Mechanical shock test setup and test setup block diagram

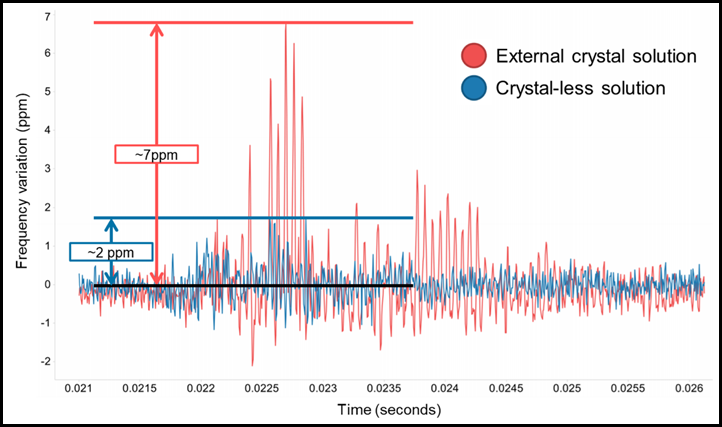

Figure 1 Mechanical shock test setup and test setup block diagram Figure 2 Comparing the maximum radio (2,440 GHz) frequency deviation (parts per million) induced by mechanical shock on both BAW and crystal devices

Figure 2 Comparing the maximum radio (2,440 GHz) frequency deviation (parts per million) induced by mechanical shock on both BAW and crystal devicesConclusion

Resources

- CC2652RB product folder, tool folder and data sheet

- “Getting started with CC2652RB for crystal-less BAW operation” application report

- SimpleLink CC13x2 and CC26x2 software development kit