SSZT356 january 2020 BQ76942 , BQ76952 , BQ76972

In recent years, consumer products like vacuum cleaners, power tools (such as drills, saws and screwdrivers) and garden tools (like mowers, edgers and lawn tractors) have moved from being corded and wall-powered to cordless and operating from rechargeable battery packs. Even previously unpowered devices like bicycles are now transitioning to battery-powered e-bikes and e-scooters.

These battery packs, which are typically constructed from individual lithium-ion, lithium-polymer or lithium-phosphate cells, can be dangerous if used incorrectly, resulting in fires or explosions. To ensure their safe use, electronics included within the pack monitor the cells so that they only operate under conditions specified by the cell manufacturer. These conditions typically include:

- The maximum allowed charging voltage.

- The maximum charging and discharging currents.

- A specified temperature range for charging and discharging.

Thus, the measurement of key parameters within the battery pack is critical, especially the voltage, current and temperature of the cells in the pack, as this data will trigger appropriate protective actions when the parameters exceed the limits.

The measurement data must be accurate so that designers can determine how much margin to include in a design. For example, if a cell specification limits the full charging voltage to 4.3 V but the measurement data has an accuracy of ±50 mV, then the designer must configure the system to disable charging whenever the measurement indicates a voltage above 4.25 V. Since the actual cell voltage may be as low as 4.2 V, however, in this case charging would stop before the cell was fully charged, resulting in wasted capacity and a shorter battery life for the application.

High-accuracy battery monitors and protectors for battery packs, like the BQ76942 and BQ76952, are designed especially for applications using lithium-ion, lithium-polymer or lithium-phosphate cells. Supporting series stacks of batteries from 3s up to 10s (the BQ76942) and 16s (the BQ76952), these devices measure cell voltage, current and temperature, and can share data with other circuitry, such as a separate microcontroller within a battery pack or the system controller in an e-bike. The BQ76942 and BQ76952 can also use the data to autonomously trigger battery protection, disabling a battery pack to avoid operation outside manufacturer specifications and re-enabling the pack again when conditions permit, with or without interacting with a host or system microcontroller.

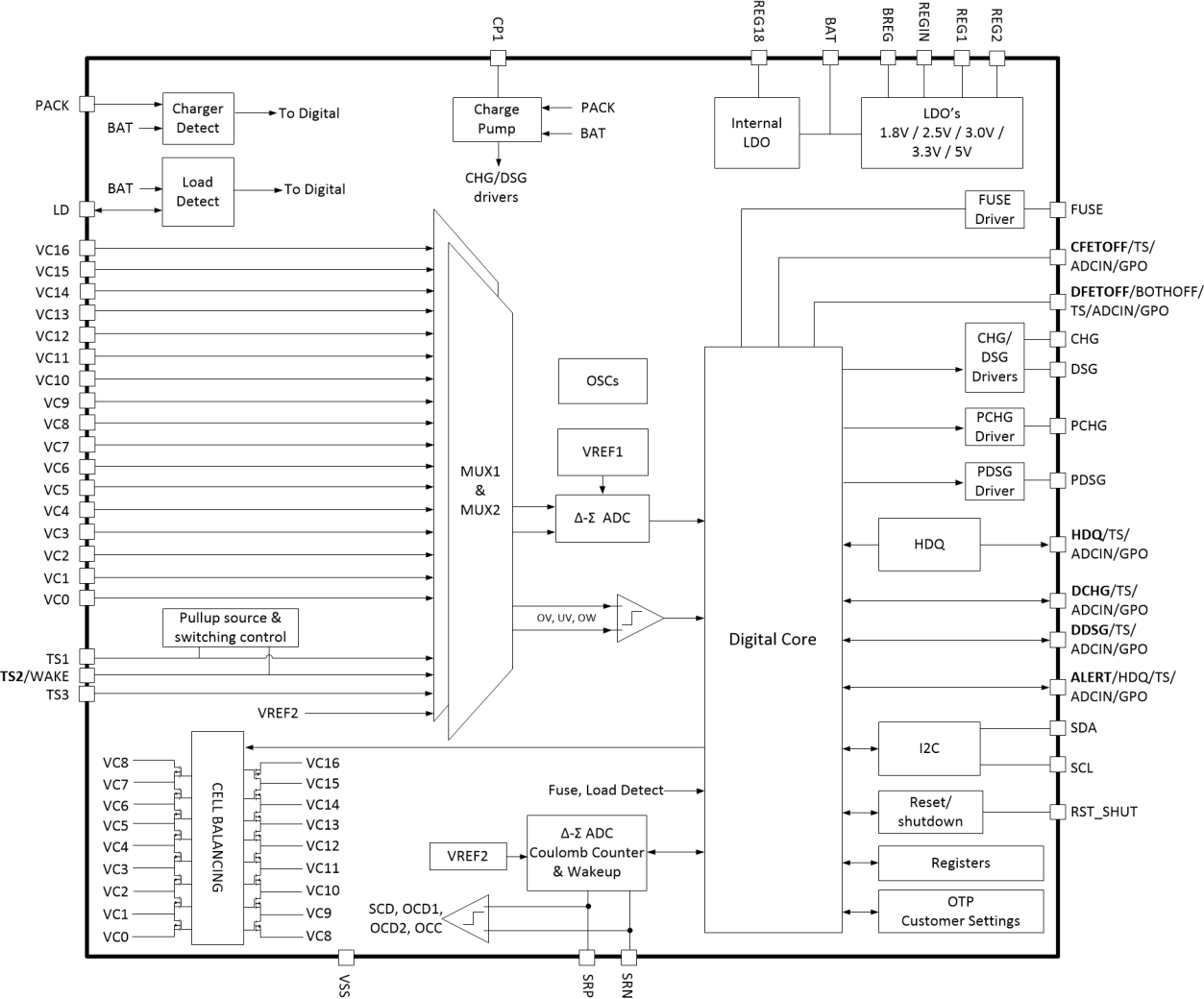

Figure 1 shows the block diagram for the BQ76952, which integrates:

- Measurement and detection subsystems, which monitor voltages, current and temperature to detect when a parameter exceeds an allowed threshold.

- Actuators for driving external protection FETs and a chemical fuse.

- A digital host interface subsystem, supporting several serial communications standards, in addition to pin controls for select functions.

- Multiple voltage regulators, one for internal circuitry, and two for external use.

Figure 1 Block Diagram of the

BQ76952

Figure 1 Block Diagram of the

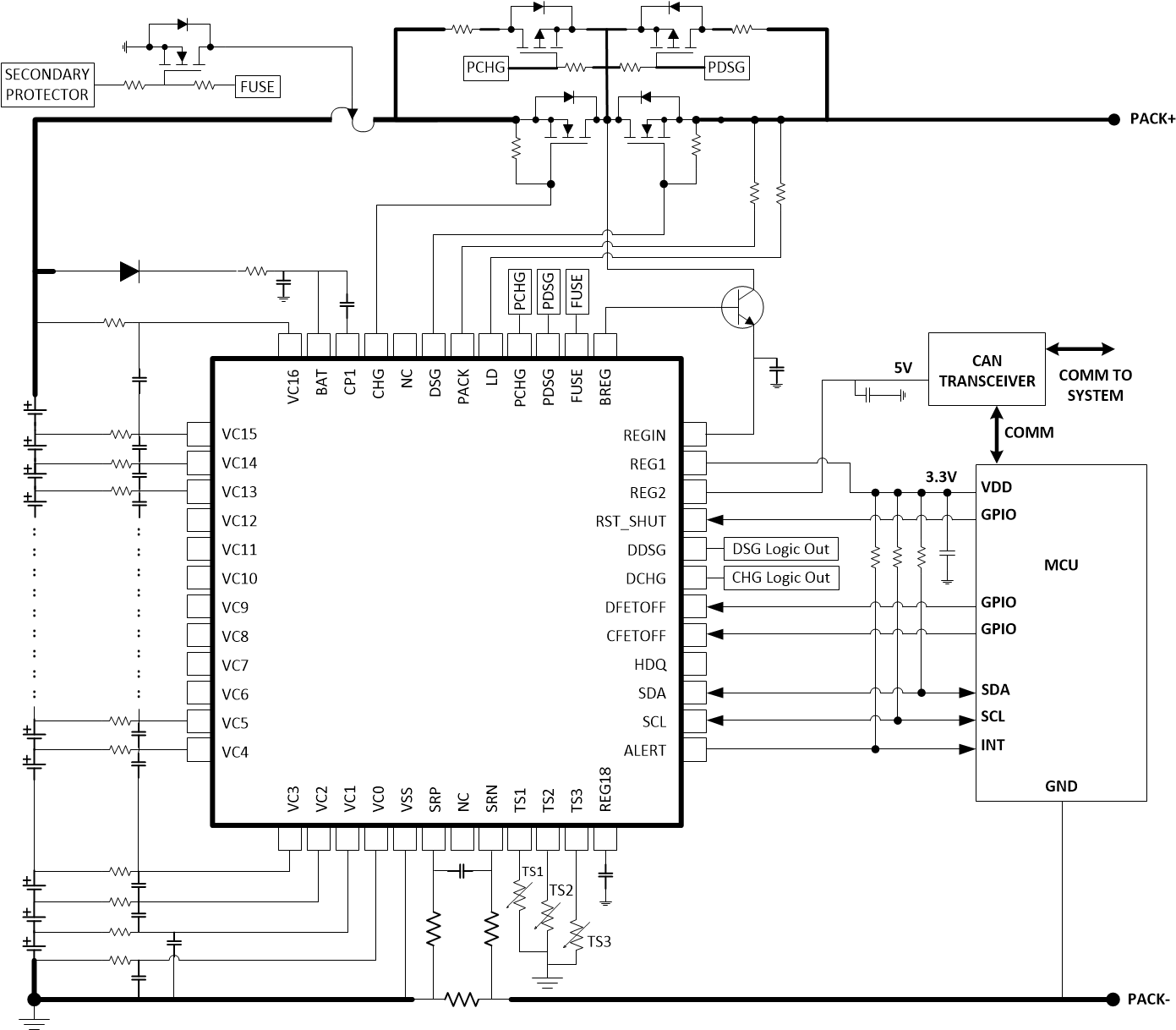

BQ76952Figure 2 shows a simplified schematic of a 16s battery pack based on the BQ76952, using I2C for communication with a host microcontroller. The integrated regulators provide supply rails for the microcontroller and an optional external transceiver.

Figure 2 Simplified Schematic of a 16s

System Based on the BQ76952

Figure 2 Simplified Schematic of a 16s

System Based on the BQ76952The measurement subsystem in the BQ76942 and BQ76952 digitizes various voltages, current and temperature within the battery pack. These measurements are obtained in different ways, due to the specific requirements for each. For example, temperature varies slowly, so it can be measured and calculated at slow intervals. However, pack current may have short bursts of activity, which can be missed if not sampled continuously.

The values generated by voltage and Coulomb-counter ADCs are processed to provide the measurement data, which is used within the device and made accessible to a separate processor within the battery pack or to the system controller in the power tool or e-bike. This data includes:

- Differential voltage of individual cells and select additional system voltages.

- Pack current and passed charge (Coulomb count).

- Internal die and up to nine external thermistor temperature readings.

Pins supporting external thermistor measurement can also be used for general-purpose ADC inputs, supporting input voltages up to ~1.8 V. The voltage ADC operates on a measurement loop, with the input multiplexed among several inputs on a periodic basis. The measurement subsystem of the BQ76942 and BQ76952 includes several programmable options to allow optimization and trade-offs between measurement speed and accuracy.

As battery-powered consumer products continue to become more prevalent, ensuring they operate within safe voltage, current and temperature ranges is essential. Battery monitors with integrated functionality can help design engineers address these three key concerns while improving accuracy. For more information about designing with TI battery monitors, please review our additional resources below.