SSZT509 march 2019 TPS54388C-Q1 , TPS57112C-Q1 , TPS57114C-Q1 , TPS62136 , TPSM831D31

There is a growing shortage of multilayer ceramic capacitors (MLCCs), and the situation is likely to persist through 2020. MLCCs are used in almost every type of electronic equipment, due to their reliability and small footprint.

While MLCC manufacturers are taking action to increase their production capacity, demand is still expected to outpace supply, resulting in supply-chain shortages and increased prices for these components.

As a power application designer, you might be wondering about how to minimize MLCC supply risks while the supply chain adapts. In this blog post, I’ll discuss several options to power a typical industrial application rail, and show how selecting the right DC/DC converter can help minimize the impact of the MLCC shortage on the production of your product.

Let’s assume that you’re looking to convert a typical 12-V input voltage into a 3.3-V regulated output, able to deliver 3 A of current. With these parameters, TI’s buck converters quick search will propose several DC/DC converter alternatives for you to choose from for an industrial application. Appropriate solutions will offer excellent thermal performance in a compact quad flat no-lead (QFN) package and efficiencies close to or even above the 90% mark at those conditions. However, specifically looking at the required MLCC count for proper operation, there will be important differences that you will have to consider.

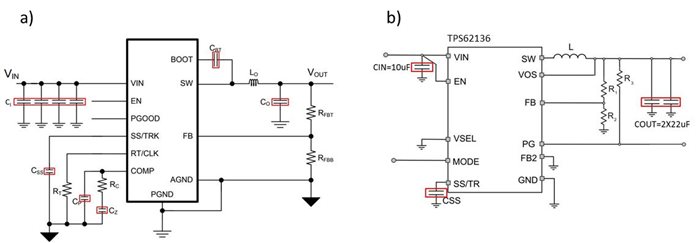

Let’s break down a typical externally compensated peak-current-control topology solution. You’ll need a small (0.1 µF) bootstrap capacitor to provide the gate voltage for the high-side metal-oxide semiconductor field-effect transistor, up to four capacitors (two 10 µF and two 0.1 µF) at the input, and a bigger (100 µF) capacitor at the output. A soft-start capacitor to control the output voltage startup ramp could be necessary, as well as two compensation capacitors for the frequency compensation network. This brings the total MLCC count up to nine for a typical circuit.

Another proposal is the TPS62136, a 3-V to 17-V input, 4-A step-down converter with the DCS-Control topology in a tiny 3-mm by 2-mm QFN package. The higher operating bandwidth and internal compensation of the TPS62136’s DCS-Control topology will enable you to minimize the output capacitor value and significantly reduce the total MLCC component count. The device’s evaluation module includes two 22-µF output capacitors only. A single 10-µF capacitor will suffice at the input, and no bootstrap or compensation capacitor is required. The use of a soft-start capacitor brings the total MLCC count to only four.

The TPS62136 comes in a package with low thermal resistance and gives efficiency close to the 90% mark for the stated conditions. It requires less than half the number of ceramic capacitors and creates a much smaller total solution size than a typical externally compensated, peak-current-mode control device. Figure 1 compares the number of required MLCCs for the circuit configurations discussed.

Figure 1 Typical Circuit Schematics for

an Externally Compensated Peak-current-mode Control Device (a); and the TPS62136

(b); the Required MLCCs Are Highlighted in Red

Figure 1 Typical Circuit Schematics for

an Externally Compensated Peak-current-mode Control Device (a); and the TPS62136

(b); the Required MLCCs Are Highlighted in RedIf you’re looking to reduce the exposure of your power application to MLCC shortage issues, make sure that the DC/DC converter you select allows you to optimize both total capacitor value and count. Our high-operating-bandwidth DCS-Control topology converter portfolio, including the TPS62136, can help without sacrificing performance.

Next week, my colleague George Lakkas will show you how TI’s D-CAP+™ control mode multiphase controllers, converters and modules, including the TPSM831D31, can help you reduce the MLCC count on your motherboard versus competitive solutions.