SSZT687A June 2018 – November 2024 INA240 , TMS320F28379D

Jun 19, 2018

In June 2017, I posted about unprecedented current-loop performance from an off-the-shelf microcontroller (MCU) achieved by the C2000™ family with the fast current loop (FCL) software solution. Closing the current loop in less than 1ms had previously been the domain of custom application-specific integrated circuit (ASIC) and field-programmable gate arrays (FPGAs) with parallel data-path architectures.

The DesignDRIVE C2000 FCL release at that time was targeted for the industrial drive development kit (IDDK) and, while you could measure the loop time with a scope, analyzing the control bandwidth of the current loop meant using an expensive dynamometer and control response analyzer tools in your own laboratory environment.

In early 2018, TI released its second version of the FCL solution, with these updates:

- Improved loop control bandwidth.

- Free software frequency response analysis (SFRA) tools.

- New low-cost evaluation tools – including the dynamometer.

- Simultaneous FCL control of two motors (dual axis) example on a single C28x central processing unit (CPU).

Better Bandwidth

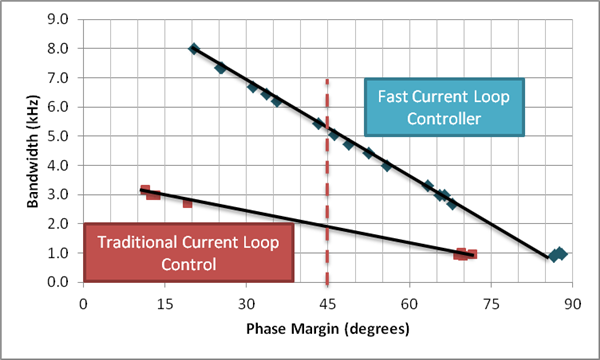

Most in the industry measure their current-loop bandwidth at 45 degrees of phase margin in order to avoid instability situations. If you compare the results in Figure 1 at 45 degrees (the dashed red line), you will see that the FCL controller delivers about 5kHz of control bandwidth, while the traditional approach is less than 2kHz.

Figure 1 Gain Margin vs. Phase Margin Results Comparing FCL to Traditional Current-loop Control

Figure 1 Gain Margin vs. Phase Margin Results Comparing FCL to Traditional Current-loop ControlFor more details on how we obtained this plot, see the technical brief, “Performance Analysis of Fast Current Loop (FCL) in Servo Drives Using SFRA on C2000™ Platform.” Or better yet, see the Additional Resources section at the end of this post and validate these measurements for yourself.

SFRA Tools, Now with Motor-control Support

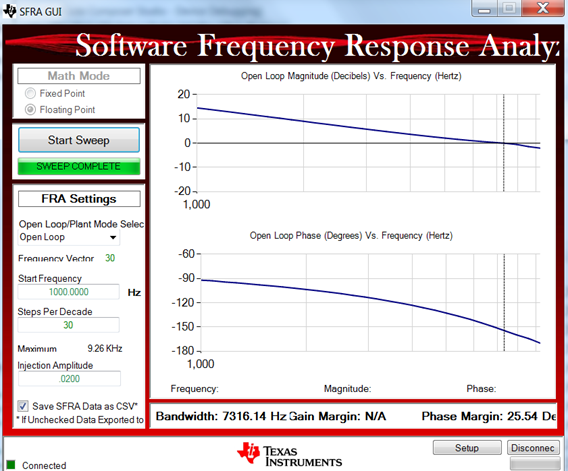

Figure 2 SFRA PC Graphical User Interface

Figure 2 SFRA PC Graphical User InterfaceBut I Need a Motor and a Controlled Load to Measure the Response

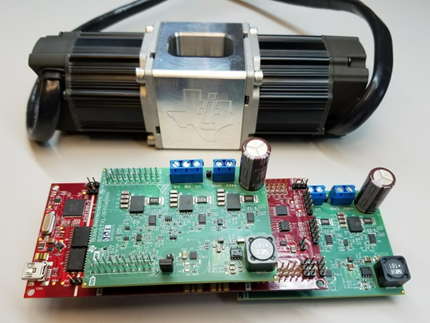

Figure 3 A Low-cost GaN-based Bundle for Motor-control Performance Testing

Figure 3 A Low-cost GaN-based Bundle for Motor-control Performance TestingAvailable for less than $600, this is the same configuration that produced the test results shown in Figure 2. The inverter BoosterPack development boards included in this bundle also include the in-phase current sensing, and therefore enable double sampling of the current per PWM period.

If you are interested in a quick way to see FCL results on your own bench and establish your own performance motor-control development and testing environment, this bundle can get you moving fast. It also serves as a great tool for testing your motor-control ideas beyond FCL – for speed and position loop control, for example.

We have also tested FCL with TI’s DRV8305N three-phase motor drive BoosterPack evaluation module with integrated sense amplifiers. In this case, the current is sampled on the inverter shunts; therefore, a single sample is taken per PWM period. These tools have also been packaged with the two-motor dynamometer and are shown in Figure 4.

Figure 4 A Low-cost, Shunt-based Sensing Bundle for Motor-control Performance Testing

Figure 4 A Low-cost, Shunt-based Sensing Bundle for Motor-control Performance TestingDual-axis Support

Additional Resources

- Download the latest FCL project controlSUITE Software projects and design files.

- Check out the FCL GaN dyno bundle, the DRV dyno bundle or just the dynamometer.

- Download the “Fast Current Loop (C28x) Library User’s Guide.”

- Download the application report, “Dual Motor Control Using FCL and Performance Analysis Using SFRA on TMS320F28379D LaunchPad.”

- Find resources and reference designs for motor drives here.

- To learn more about TI’s FCL solutions for C2000 MCUs, check out: