SSZT850 December 2017 LP87524B-Q1 , TPS54388C-Q1 , TPS54618-Q1 , TPS57112C-Q1 , TPS57114C-Q1

It’s been said that if you only have a hammer, you’ll see every problem as a nail. When it comes to powering automotive processors, you’ll find hammers, screwdrivers and more in TI’s extensive portfolio of highly integrated power-management ICs (PMICs). My colleague Karl Wallinger describes the benefits of these devices in his blog post, “How an integrated power management IC can simplify your infotainment or ADAS system.” However, your power designer’s toolbox is not complete without also considering discrete buck converters. In this post, I’ll illustrate a few situations where the flexibility of buck converters makes them a good choice for automotive point-of-load (POL) power.

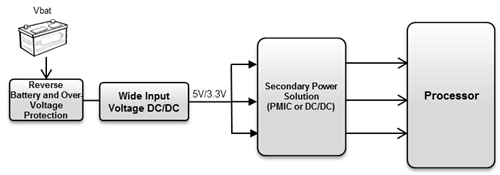

Regardless of the specific system they’re used in, the processor power trees for advanced driver assistance systems (ADAS) and infotainment systems tend to look fairly similar. The car battery supplies its nominal 13.5V output through an overvoltage protection IC to a wide input voltage buck converter. The wide VIN converter then supplies 5V or 3.3V to several POL converters, which convert down to the voltage levels required by the processor. Figure 1 illustrates this common architecture.

Figure 1 Common Power Tree for ADAS and

Infotainment Systems

Figure 1 Common Power Tree for ADAS and

Infotainment SystemsYou can easily adapt this basic solution to a variety of system needs, with either one integrated PMIC (one IC with multiple power converters inside) or multiple discrete, single-output converters supplying the processor power. The biggest benefit of using discrete converters is their flexibility in the face of changing system power requirements. Figure 2 shows a typical power tree of a surround-view camera electronic control unit (ECU) using a discrete buck converter solution.

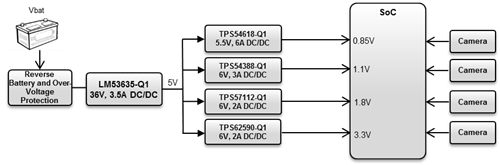

Figure 2 Typical Power Tree for a

Surround-view System ECU

Figure 2 Typical Power Tree for a

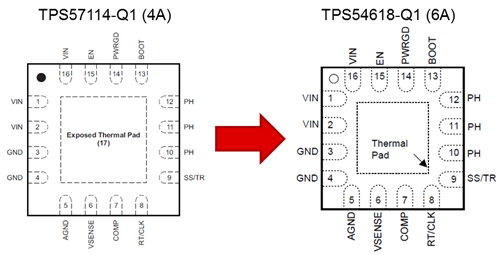

Surround-view System ECUIn this layout, there is one buck converter for each power rail on the system on chip (SoC), which might seem a bit more complex than an integrated solution. One other consideration, however, is the trend of increasing processor power requirements. Just a few years ago, the processor core rail may have required only 4A. All other things being equal, you’d likely be inclined to use the LP87524B-Q1, a PMIC that can supply a 4A rail, a 2.5A rail, and two 1.5A rails, and capture the full power tree in one device. Unfortunately, when you discover later in the design process that your core rail needs more power than you initially thought, your board will need to change radically. This won’t happen with discrete converters, where you can quickly remedy the issue by removing the 4A TPS57114-Q1 and replacing it with the footprint-compatible 6A TPS54618-Q1. Sure, there will be some board layout changes, but you won’t need to rebuild the power tree from the ground up – and you’ll ultimately save design time by leaving the lower-current rails untouched. Figure 3 illustrates this easy scalability.

Figure 3 Pin Compatibility Makes Scaling Core Power Easy

Figure 3 Pin Compatibility Makes Scaling Core Power EasyOn the flip side, you might find yourself looking to scale your solution down to a more cost-optimized, less processor-power-hungry version. Using the same PMIC is a quick and easy solution, but it’s not possible to simply “remove” an output that you’re not using. You’ll be paying (in both price and board space) for one or more channels that serve no function in the system. In the case of a discrete solution, removing one or more power rails from an existing design is as simple as not populating the components on the board. There, you’re getting (and using) exactly what you pay for.

PMICs are becoming an increasingly common solution for secondary power in ADAS and infotainment systems thanks to their high level of integration and ease of power sequencing. They’re great solutions for these applications, but discrete DC/DC converters also provide benefits in terms of flexibility and scalability. Next time you open your toolbox to start a power design, make sure your trusty buck converters are inside. You can find all of TI’s automotive secondary DC/DC converters here.