SSZT943 september 2017 TIOL111 , TIOL1115 , TIOS101 , TIOS1015

In my last post, I discussed the future of factory automation and how IO-Link is an enabling interface for Industry 4.0. You can use the IO-Link bidirectional, manufacturer-independent communication protocol to develop highly efficient and scalable “smart factories.”

TI’s TIOL111 IO-Link transceiver and TIOS101 digital output switch will enable the next generation of sensors and actuators in factories, while providing features that further optimize product offerings and simplify bill of materials.

You can take advantage of the pin compatibility between the TIOL111 and TIOS101 devices to develop a complete portfolio of both IO-Link and standard input/output (SIO) enabled sensors without using two separate printed circuit boards (PCBs) for each offering. Each device supports the interfaces intended while also supporting a high level of integrated protection, including:

- 16kV International Electrotechnical Commission (IEC) 61000-4-2 electrostatic discharge (ESD).

- 4kV IEC 61000-4-4 electrical fast transient (EFT) Criterion A.

- 1.2kV/500Ω IEC 61000-4-5 (surge).

- ±65V transient tolerance.

- Reverse polarity up to ±55V.

- Overcurrent/overvoltage/overtemperature.

This level of protection can simplify designs by eliminating or greatly reducing the size of external transient voltage suppression (TVS) diode components that originally provided protection, thus reducing the overall bill of materials and associated costs when compared to previous-generation or competitive solutions.

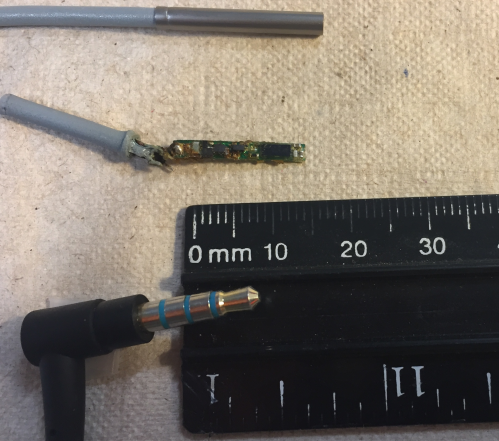

The physical size of sensors continues to shrink. The smallest of these sensors is likely the cylindrical sensor, as shown in Figure 1.

Figure 1 IO-Link Cylindrical

Sensor

Figure 1 IO-Link Cylindrical

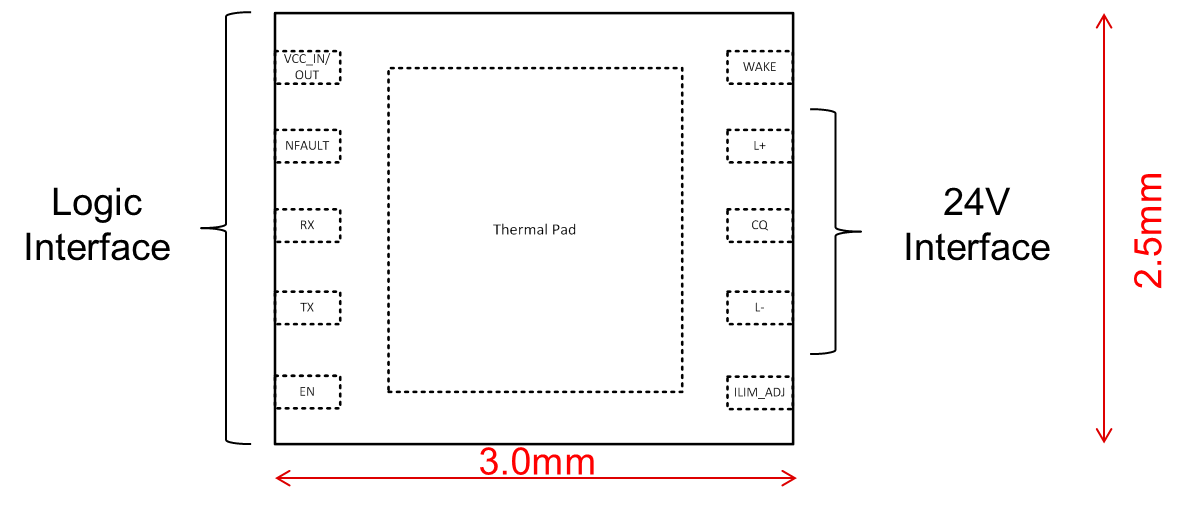

SensorThe sensor at the top of Figure 1 is the finished product with a cylindrical enclosure. The middle wire is the sensor’s internal printed circuit board (PCB). This PCB measures 17.5mm by 2.5mm. In order to fit in these small form factors, an equally small device is required to implement either IO-Link or SIO output. Knowing these system requirements drove a new package development for TIOL111 and TIOS101 solutions. The DMW package is one of the smallest, thermally enhanced IO-Link packages available today. Measuring 3.0mm by 2.5mm, the DMW package also supports a thermal pad for heat conduction and a flow-through pinout. The flow-through pinout (Figure 2) further aides in PCB layout and device placement by supporting the logic interface to the microcontroller on one X-axis and the 24V IO-Link interface on the other.

Figure 2 TIOL111/TIOS101 flow-through

package

Figure 2 TIOL111/TIOS101 flow-through

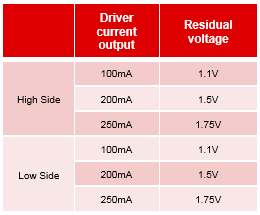

packageThe TIOL111 and TIOS101 have a low residual voltage of just 1.75V – the size of sensors that use IO-Link and SIO are rugged, sealed and often very small. This small, enclosed form factor introduces numerous design challenges, with thermal performance one of the most challenging. By supporting an ultra-low residual voltage of 1.75V at 250mA, the TIOL111 and TIOS101 provide a superior base for power dissipation and related system thermal management.

|

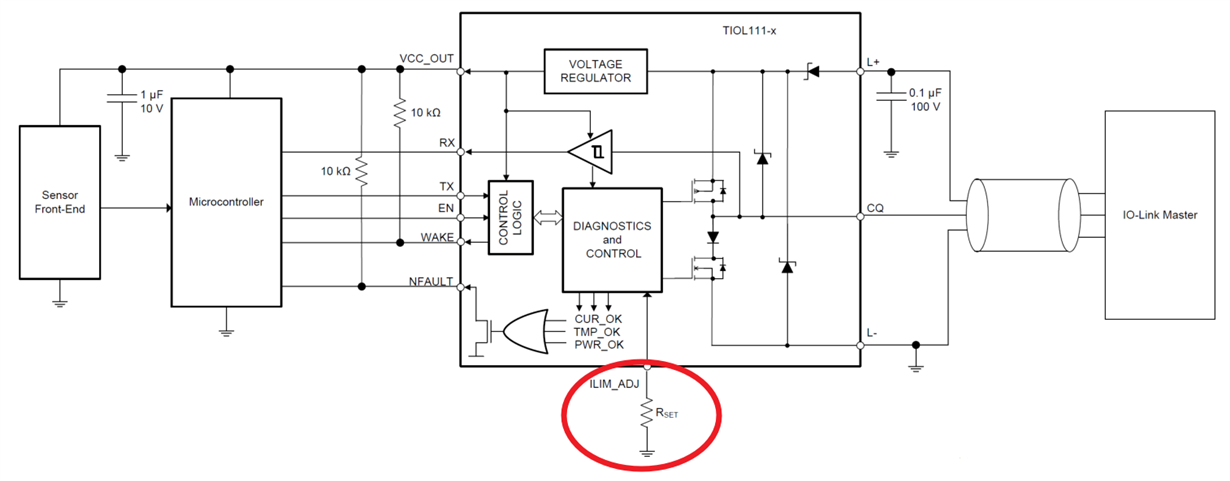

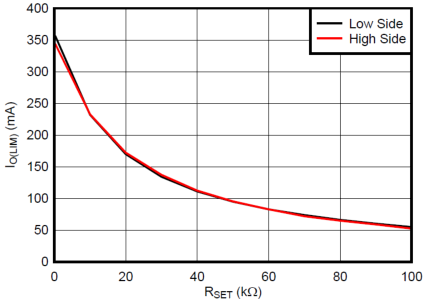

Configurable current limit is an additional protection feature that can protect the sensor and possibly prevent the network from shutting down. Through a 0-100kΩ resistor, the TIOL111 and TIOS101 can support a 50-350mA current limit. This limiter can notify the programmable logic controller (PLC) of an overcurrent condition and shut down the device's output, with periodic monitoring of the overcurrent condition.

The configurable current-limit resistor is placed on the ILIM_ADJ pin (see Figure 3).

Figure 3 TIOL111 application

schematic

Figure 3 TIOL111 application

schematicAs Figure 4 indicates, using a 0Ω resistor on the ILIM_ADJ pin will default to the maximum current limit of 350mA (see Figure 4)

Figure 4 Current limit vs.

RSET

Figure 4 Current limit vs.

RSETThese and other features and benefits of the TIOL111 and TIOS101 can enable the smallest sensor form factors, while providing the flexibility to support multiple platforms and current configuration requirements.

Additional Resources

- Learn more about TI’s line of IO-Link and digital output switches.

- Evaluate your device today with the TIOL1115 and TIOS1015 evaluation modules.

- Download the Smart Solenoid Driver with Predictive Maintenance Reference Design featuring the TIOL111.