SSZT945 september 2017 MSP430FR6047

Ultrasonic technology has been in use for over a hundred years in several civil, medical and military applications. Almost everyone in the developed world has experienced medical ultrasonic technology (even before birth!); however, most recent advancements and use cases have been in automation for industrial and automotive markets.

It’s amazing to see this technology find its place in a diverse set of applications. Its noninvasive (noncorrosive) or contactless properties make it a great candidate for medical, pharmaceutical, military and factory uses. Plus, its operational environment is outside a range audible to humans.

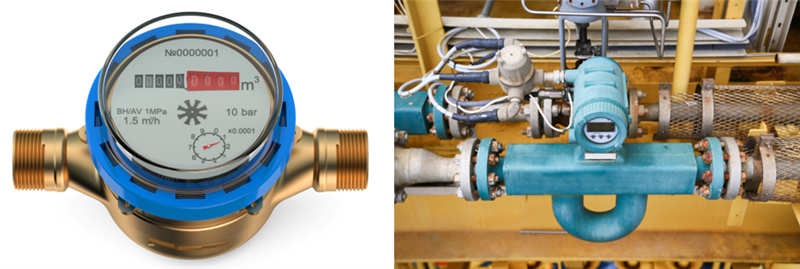

Flow measurement is the quantification of flow or the rate of flow of a liquid or gas, measured in units such as liters per hour (lph) or gallons per minute (gpm). You’ll find flow meters in residential and industrial environments, including simple utility meters (gas, water, heat) in homes and industrial gauges or mixers for hazardous liquids or gases (petroleum, mining, wastewater treatments, paints, chemicals); see Figure 1. Architecturally, a flow meter comprises three units: a sensor unit, a measurement unit and a communications unit. Each of these units or functional blocks can be mechanical or electronic.

Figure 1 Examples of Flow Meters in

Residential and Industrial Applications

Figure 1 Examples of Flow Meters in

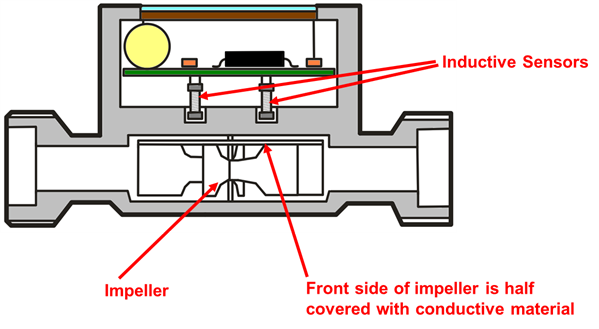

Residential and Industrial ApplicationsA variety of flow-meter designs use mechanical sensing, which of course means moving parts. Inductor capacitor (LC), giant magnetoresistive (GMR), tunnel magnetoresistive (TMR) or Hall effect sensors capture the movement of a propeller or impeller that changes in accordance with the flow, which is translated into data and passed to the measurement unit. Because there are moving parts, there is the potential for wear and tear and inaccuracies.

Media contamination, dirt accumulation, and the scaling and aging of components can also affect accuracy, requiring periodic recalibration of the flow meter. There is also the potential for tampering, leading the sensor to report inaccurate results. These meters have a short lifetime (less than seven years) and are not capable of measuring low flow or small leaks. Figure 2 shows a rotary-based water meter with LC sensors.

Figure 2 Rotary-based Flow Meter Using

LC Sensors

Figure 2 Rotary-based Flow Meter Using

LC SensorsUltrasonic sensing mitigates several of the issues I mentioned above. This sensing technique is very accurate (< ±1%) with a long operational life (>10 years) and can easily detect a variety of materials and adjust to the effects of contamination in media and pipe corrosion. Ultrasonic meters have no moving parts and thus no need for recalibration, nor any concerns related to the accumulation of dirt or aging.

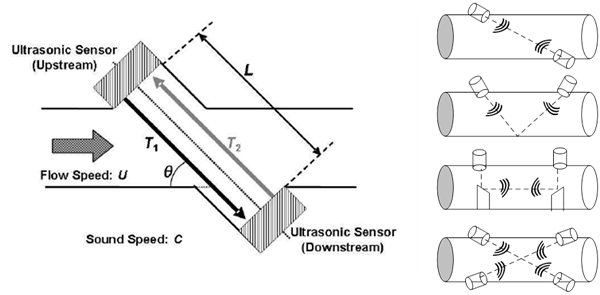

Ultrasonic sensing for flow measurement primarily calculates the propagation delay of sound at frequencies between 100kHz and 4MHz. Electronic pulses excite transducers, causing them to transmit upstream and downstream sound waves. The time difference, also known as the time-of-flight (TOF) between the upstream and downstream waves, gives the actual flow rate.

One or more pairs of ultrasonic sensors positioned inside or outside the flow tube detect the speed of flow from the measured TOF. Figure 3 shows a typical ultrasonic sensing concept and some topologies for transducer placements in a pipe. The choice of ultrasonic sensors depends on the type of medium that needs flow measurement. Typically, liquid sensing uses sensors higher in the frequency spectrum (>1MHz), while gaseous media will be on the lower end (<500kHz).

Figure 3 Examples of Ultrasonic Sensing

for Flow Meters and Common Topologies for Positioning within a Pipe

Figure 3 Examples of Ultrasonic Sensing

for Flow Meters and Common Topologies for Positioning within a PipeThe accuracy of the TOF directly translates to the flow measurement resolution and accuracy, typically measured in picoseconds (ps) or nanoseconds (ns). Other important figure of merits are zero flow drift (ZFD), single-shot standard deviation (STD), minimum and maximum detectable flow, flow rate, volume, absolute (Abs) TOF and Delta (Δ) TOF.

Several standards govern accuracy; the most common are International Organization for Standardization (ISO) 4064, Organisation Internationale de Métrologie Légale (OIML) R49 and European Standard (EN) 1434. Achieving standards-compliant accuracy requires a high level of precision. There are several methods to determine TOF, including time to digital conversion, zero crossing detection and cross-correlation using waveform capture.

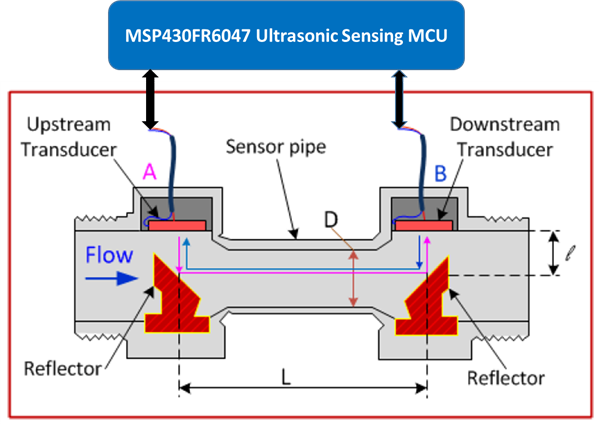

TI’s MSP430FR6047 microcontroller (MCU), a highly integrated system on chip (SoC) for water-flow measurement, is tailor-made for accurate TOF using ultrasonic sensing technology, with a novel analog-to-digital converter (ADC)-based waveform capture. Figure 4 shows a simple interface of ultrasonic transducers to this MSP430™ MCU.

Figure 4 An MSP430 MCU Interface to

Ultrasonic Flow Transducers in a Pipe

Figure 4 An MSP430 MCU Interface to

Ultrasonic Flow Transducers in a PipeA pair of ultrasonic transducers directly interface to the MSP430FR6047 MCU’s integrated ultrasonic sensing subsystem peripheral. Flexible options enable the independent excitation and response capture of each transducer using a high-speed 8MSPS sigma-delta (or delta-sigma) ADC. Further processing of the captured waveform includes a combination of several digital signal-processing algorithms and functions. The waveform capture method in the MSP430FR6047 MCU provides best-in-class resolution (<5ps) – a breakthrough system design for liquid and gaseous sensing in residential and industrial environments.

Because a majority of ultrasonic water flow meters are battery-powered, the ultra-low power of the MSP430FR6047 MCU offers long battery life (10+ years) with only ~3µA average current consumption. Additionally, you can easily extend this architecture to heat meters, which are simply the product of flow rate measured for liquid and the temperature gradient between forward and backward flows.

Ultrasonic sensing for flow measurement brings together the advantages of lower size, lower cost, improvements to accuracy and robustness, extended product lifetimes, and connectivity to smart grids.

Additional Resources:

- Download the “Ultrasonic sensing technology for flow metering” white paper.

- To learn more about MSP430FR6047 here.

- Watch our ultrasonic sensing video series.

- Request an EVM430-FR6047 evaluation module online today.