SSZT963 september 2017 AMIC110

Factory production lines that go down unexpectedly due to automation technology failures are expensive for factory owners. Production stops, the assembly line workers are idle and the service engineers need to find the root cause as quickly as possible.

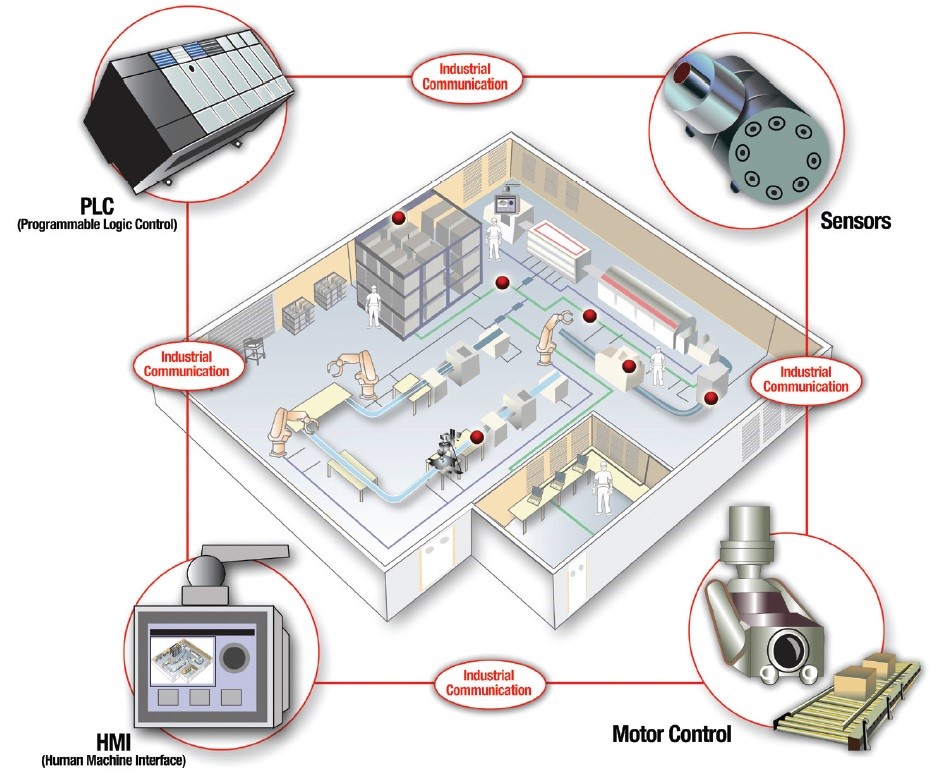

Many failures in automation technology are caused by worn-out industrial communication Ethernet cables; see Figure 1. These failures are hard to pinpoint, as they can occur anywhere between two devices that are as much as 100m apart.

Figure 1 A Factory Automation

Production Floor with Industrial Communication (Such as Industrial Ethernet)

Connecting Programmable Logic Controller (PLC) and Field Devices

Figure 1 A Factory Automation

Production Floor with Industrial Communication (Such as Industrial Ethernet)

Connecting Programmable Logic Controller (PLC) and Field DevicesPredictive maintenance for industrial Ethernet can reduce factory downtimes to a minimum. Automation technology components (PLC, sensors/actuators, digital input/output, servo drives) that support predictive maintenance for industrial Ethernet can scan the Ethernet cables and exactly locate the failure on an assembly line. The maintenance or service engineer receives the failure analysis over an Industry 4.0 network and knows which broken industrial Ethernet cable section to replace. Even before a production line goes down, service engineers can receive notifications to replace Ethernet cables detected just as they are beginning to wear out.

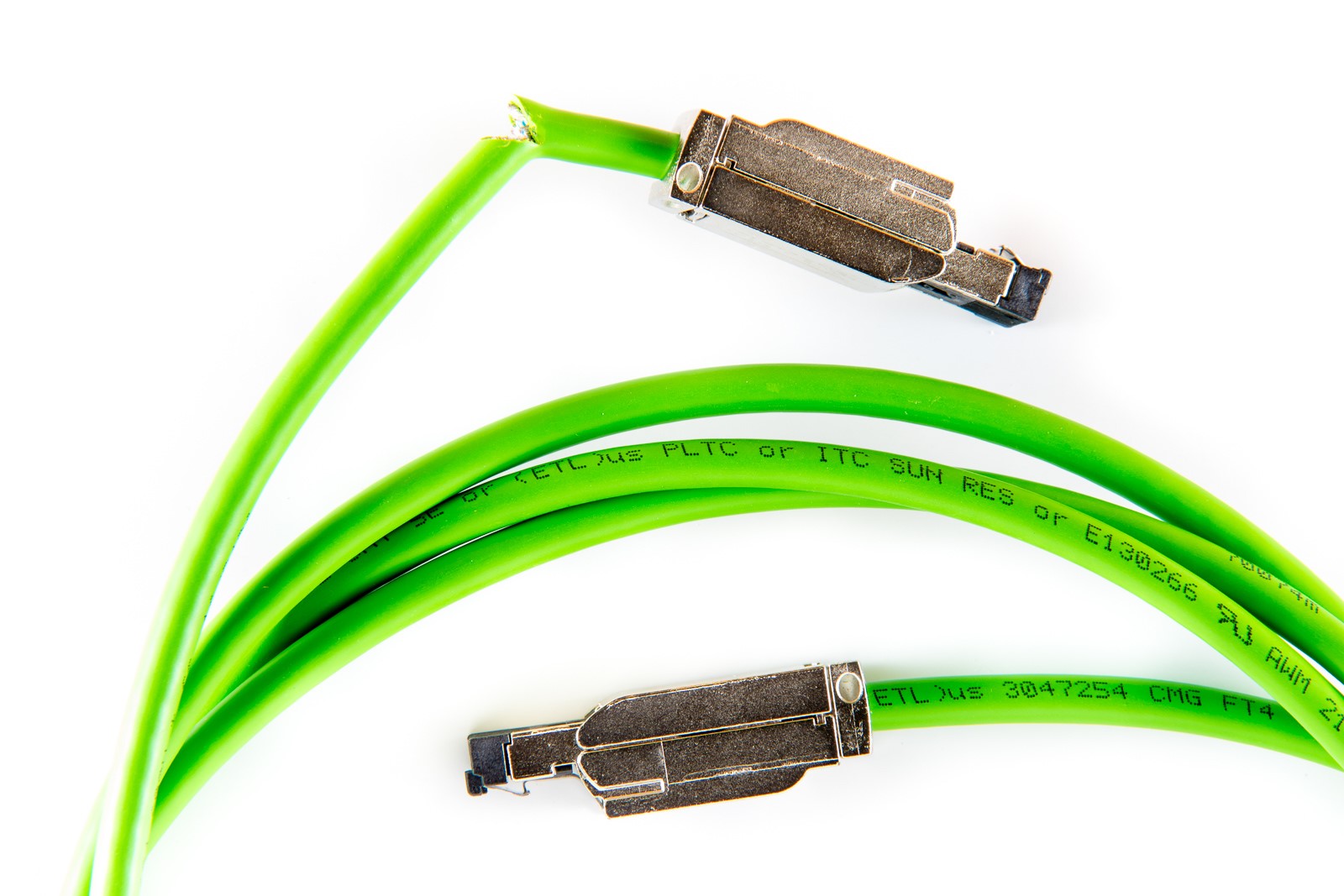

Predictive maintenance for industrial Ethernet is a feature in the physical layer (PHY) that has to be integrated and supported by automation technology devices in order to detect and diagnose industrial Ethernet cable faults. Predictive maintenance (It) enables the automation technology devices to detect Ethernet cable defects as seen in Figure 2.

Figure 2 Broken Industrial Ethernet

Cable

Figure 2 Broken Industrial Ethernet

CableHere is a list of industrial Ethernet cable defects:

- Open connection: the Ethernet cable is unplugged from a device or has been mechanically cut in half.

- Shorted lines: the Ethernet cable is damaged and wire lines have a short to each other.

- Single-pair failure: the Ethernet cable is damaged and the receiver (RX) or transmit (TX) pair is cut in half.

- Single-line failure: the Ethernet cable is damaged and a single wire is cut in half.

- Connector corrosion: a sneaky failure, because it occurs slowly over a long period of time. Industrial communication is occasionally broken between devices, although it works most of the time.

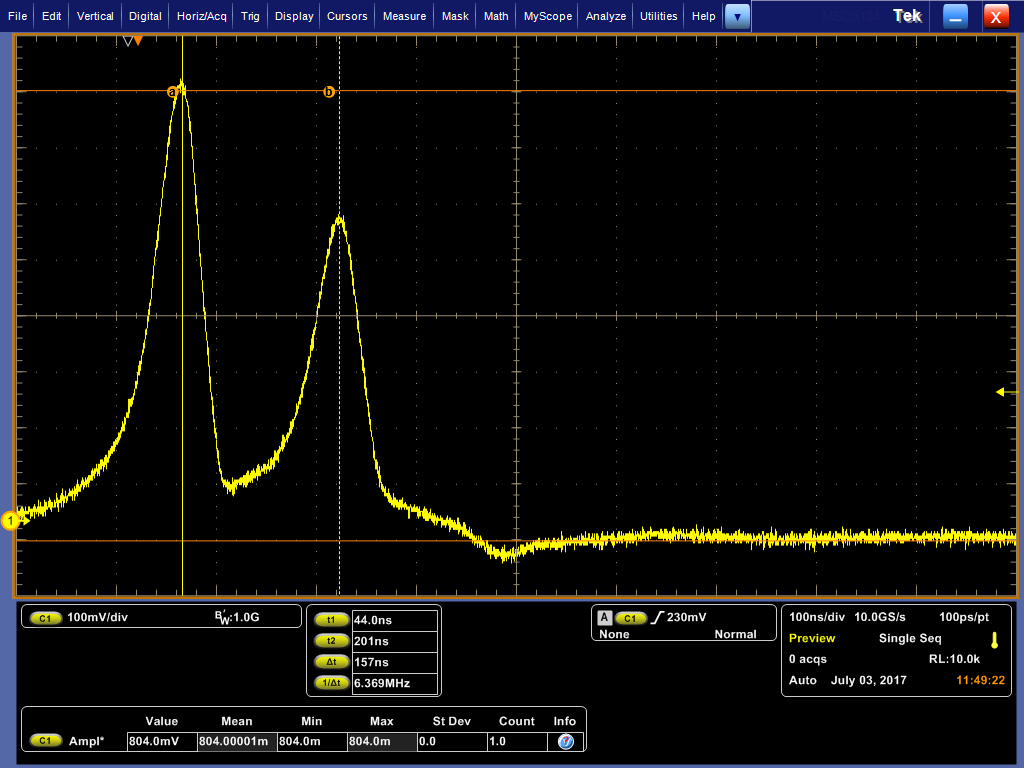

To identify Ethernet cable defects, the industrial Ethernet PHY has to support time-domain reflectometry (TDR) and active link cable diagnostics (ALCD).

TDR works like this: the initiator Ethernet PHY sends out a very short pulse over the Ethernet cable to determine if this pulse is reflected at the far end. There is no reflection of the pulse when the Ethernet cable properly terminates at the far end. If the Ethernet cable has a defect, however, the pulse is reflected and travels back over the Ethernet cable to the initiator PHY. The initiator PHY analyzes the short pulse reflection and determines the type of Ethernet cable defect from among those listed above.

Figure 3 shows two pulses for an open-connection Ethernet cable defect, measured at the initiator PHY. The initiator PHY generates the first pulse. After some time it receives the second pulse. The distance between the two pulses is the “echo” of the reflected pulse. With the Ethernet cable propagation delay (~5ns per meter), the cable defect is located at 30m. The positive amplitude of the reflection tells the initiator PHY that this is an open-connection Ethernet cable defect.

Figure 3 TDR Pulse and TDR Reflection

for an Open 10m Ethernet Cable

Figure 3 TDR Pulse and TDR Reflection

for an Open 10m Ethernet CableALCD is a passive method that estimates the cable length during an active link. It uses passive digital signal processing based on received data, thus enabling cable-length measurements with an active link partner.

TI’s DP83822 (10/100Mb) and DP83867 (10/100/1000Mb) industrial Ethernet PHYs support TDR and ALCD predictive maintenance features. Figure 4 shows the low pin-count package of the DP83822 PHY, ideal for automation technology devices with little PCB space. A management data input/output (MDIO) register interface initiates and reads out predictive maintenance functions without disrupting the industrial Ethernet communication.

The DP83822 and DP83867 automatically start TDR analysis when the link partner goes down. The type of Ethernet cable defect is reported back to the PLC and sent though Industry 4.0 networks to factory operators, informing them that maintenance is required.

Figure 4 The DP83822 Ethernet PHY

Supports TDR and ALCD Preventive Maintenance Features

Figure 4 The DP83822 Ethernet PHY

Supports TDR and ALCD Preventive Maintenance FeaturesTo reduce downtime to a minimum, factory owners need to invest in automation technology that supports predictive maintenance for industrial Ethernet. Automation technology device manufacturers should consider implementing predictive maintenance into their equipment to differentiate their products in the competitive factory automation and control market.

Additional Resources:

- Test predictive maintenance functions with the AMIC110 industrial communications engine.

- Read the industrial Ethernet blog post series if you are interested in field bus and industrial Ethernet communication.

- Download the application report, “How to use the TDR feature of DP83822”.