SSZTA81 april 2017 DRV8802-Q1

When I was a kid, my dad bought a big green Buick tricked out with all the bells and whistles – an AM/FM stereo with a rear speaker and reverb knob, electric windows, and most importantly power bench seats. The car was such a big deal that other kids from the neighborhood came to sit in it, and my sister and I made the seats go forward and back.

The first power seats (like in my dad’s Buick) had one or two electric-powered adjustments – primarily forward/backward and back support tilt. Really early cars had seats that didn’t adjust at all; Ford’s Model T seats look like built-in sofas, comfortable enough for low speeds but primitive in terms of features and safety.

Fast-forward to the present day, and seats have become a complex subsystem of a car. In terms of driver (or passenger) support, they do more than just provide a chair. They provide an ergonometric platform with precise support against downward gravity, longitudinal acceleration and lateral (turning) forces.

In addition, modern power seats provide the ability to adjust every aspect of the seat – distance from the steering wheel, seat height, seat tilt, lumbar support – in order for the occupant to feel comfortable. They may provide a heated or cooled cushion and back massage to enhance comfort. Seats can even rumble to the beat of the sound system or shake the driver if they drift out of their lane or seem drowsy. Modern seats measure our weight to determine air-bag settings and provide head rests to reduce neck injuries in case of a collision.

Motors make all of these seat adjustments possible. Most seat motors are rotary brushed DC (BDC) motors, although some applications are exploring electronically commutated brushless DC (BLDC) motors to reduce weight and eliminate brush wear and noise.

Driving Seat Motors

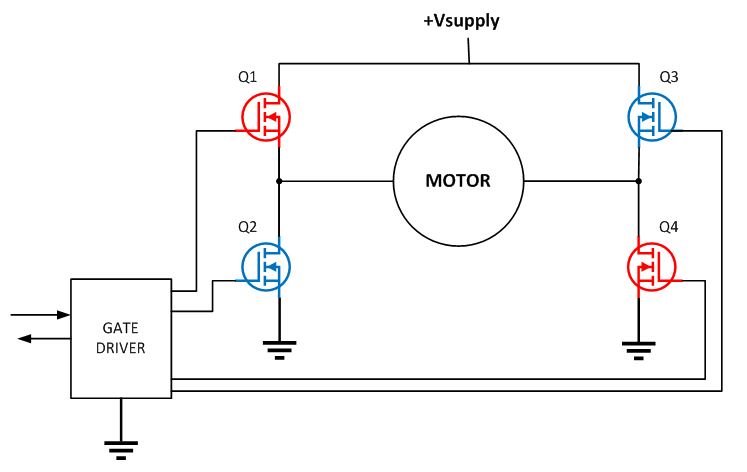

Figure 1 H-bridge Configuration of Transistors to Enable Bidirectional Motor Rotation

Figure 1 H-bridge Configuration of Transistors to Enable Bidirectional Motor RotationMechanized gear trains convert the high-speed, low-torque rotary motion of a BDC motor to high torque, low-speed motions for seat adjustments. Even with the mechanical advantage of the gears, the power needed to adjust the occupied seat means that these motors will need several amps of current. In drive electronics, this implies either hefty automotive relays or, as most designers are now using, low RDS(ON) metal-oxide semiconductor field-effect transistors (MOSFETs) for the switches in a full bridge.

A gate driver typically drives the four N-channel FETs, providing voltage level shifting for switching the high-side devices. The gate driver will usually also ensure that the high and low FETs on one side are never on simultaneously, preventing a short circuit (or shoot-through current) from the supply to ground.

Simplifying Seat Motor Driver Electronics

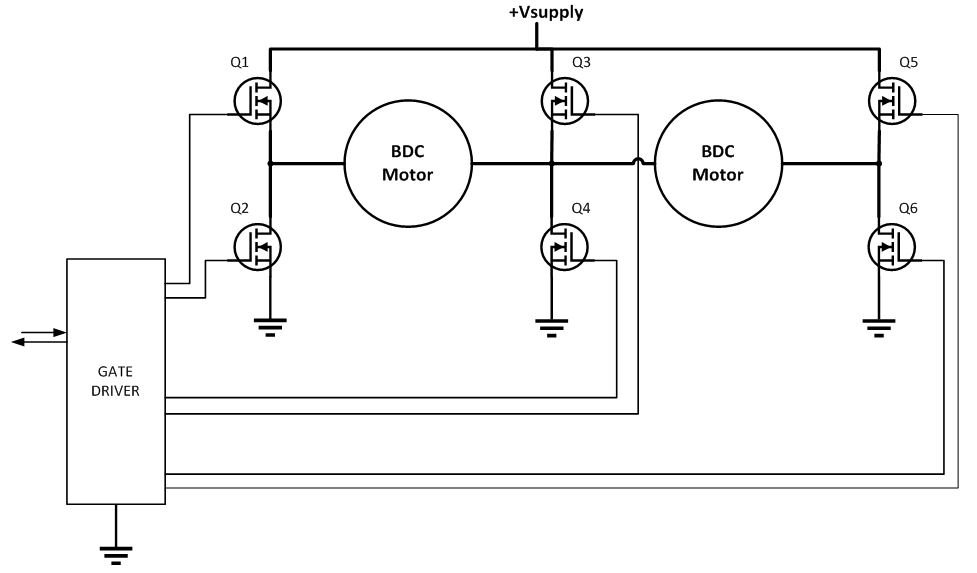

Figure 2 Sharing MOSFETs between Motors Simplifies Seat Motor Driver Electronics

Figure 2 Sharing MOSFETs between Motors Simplifies Seat Motor Driver ElectronicsOverall, I expect several trends to continue in automotive seating. The seat will continue to have more motors, drive electronics will continue to evolve from relays to MOSFETs, and the seats themselves will continue to integrate more features. Seats are becoming smarter, safer and more comfortable with each new design. So don’t be surprised when the neighborhood kids want to get a lumbar seat massage in your 2019 model.

Additional Resources

- Using Texas Instruments’ DRV8802-Q1 brushed DC motor driver, the Automotive HVAC Multiple Flap Actuator/Damper DC Motor Driver Reference Design connects and controls multiple flap motors.

- For DC motor reference designs, check out the Automotive 12V 200W (20A) BLDC Motor Drive Reference Design.

- The Body Electronics and Lighting page has more automotive body electronics and lighting reference designs.

- Check out “The other motors in electric vehicle systems” blog series on Motor Drive and Control