SSZTAH5 january 2017 ISO7820LL , ISO7821LL , ISO7821LLS

Isolation, as you know, is used in a wide variety of applications: to protect human operators and low-voltage circuitry from high voltages, to improve robustness to noise, and to handle ground potential differences between communicating subsystems. A myriad of isolation products exist in the market: digital isolators, isolated controller area network (CAN) and RS-485 transceivers, isolated amplifiers and modulators, isolated gate drivers, and isolated power supplies. This post is about the new stars added to the constellation of isolation products – isolated low-voltage differential signaling (LVDS) devices, or isolated LVDS.

I put together this Q&A about isolated LVDS devices, and what they can do for your application.

Q: What is isolated LVDS?

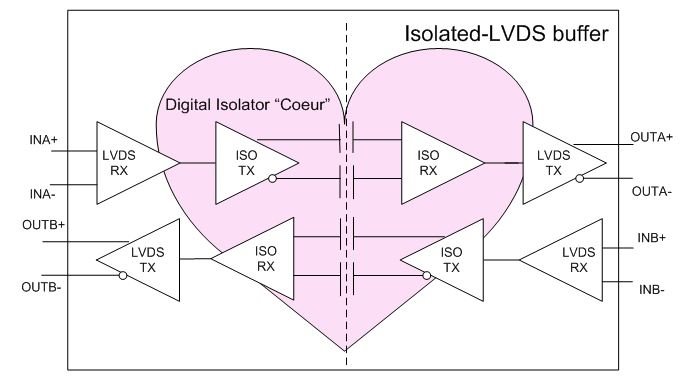

A: Isolated LVDS is a device that can talk and hear your everyday differential low voltage but at its heart is a good old-fashioned digital isolator. See Figure 1.

Figure 1 A Digital Isolator at the

Heart of an Isolated LVDS Buffer

Figure 1 A Digital Isolator at the

Heart of an Isolated LVDS BufferQ: Why use isolated LVDS?

A: Well, sometimes you have to. If you are isolating two subsystems, need to transfer high-speed data between them, and that data needs to travel between two boards through long traces, connectors or cables, then you can’t use regular digital isolators. They will take up too much power, emit too much radiation and the eye diagram at the far end won’t be much to look at. Complementary metal-oxide semiconductor (CMOS) won’t take you far, literally. The answer? Isolated LVDS.

Q: In what applications can you use isolated LVDS to your advantage?

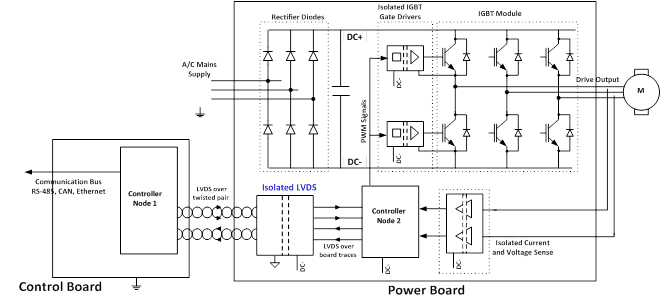

A: Motor drive is a prime example. More and more drives are including a controller on the power board for local processing (shown in Figure 2). Often, an aggregate of many control and feedback signals needs to be transferred to a master controller on the low-voltage side – on a different board. An isolated LVDS device can manage the data deluge.

Other applications include test and measurement and high-power solar inverters.

Figure 2 Isolated LVDS in a Motor Drive

Application

Figure 2 Isolated LVDS in a Motor Drive

ApplicationQ: What specifications distinguish isolated LVDS products?

A: The first is, of course, isolation performance. Depending on the application, reinforced, basic or functional isolation may be required. For a motor-drive application, the isolated LVDS is critical to protective isolation. The isolation requirements can be very high, and are proportional to the drive’s AC line voltage. Other specifications of interest include low power consumption, low emissions, high immunity to noise, high data rates, and low propagation delays and skews. These other advantages are inherent to LVDS signaling, but it is important that the digital isolator at the core also share these excellent virtues.

Before you start designing with isolated LVDS, check out the ISO7821LLS, ISO7821LL and ISO7820LL LVDS buffers. Suitable for very high voltage applications, these buffers contain reinforced isolation up to a 2kVRMS working voltage, 12.8 kV surge and extra wide package options. Also, with data rates up to 150Mbps, very low emissions, and consuming only 10mA/channel at max data rates, these devices bring out the best benefits of LVDS operation.

Would you like to know more? Read this longer article on EDN or leave a comment below.

Additional Resources

- Download the ISO7821LLS, ISO7821LL and ISO7820LL data sheets.

- Read more of my blog posts about isolation.

- Start designing quickly with the High-Performance Isolated Dual LVDS Unidirectional Buffer Evaluation Module (EVM).

- View TI’s isolation portfolio.