SSZTAJ0 december 2016 AMC1301 , DCH010505S , OPA320 , OPA4350 , PTH08080W , TMS320F28377D , UCC21520

Whenever I have a conversation about electric vehicles (EVs), I often hear the opinion that these vehicles do not have enough range to drive long distances. To a large extent that is true, even though Tesla and several other car vendors are rolling out vehicles in the +200-mile range. But there is also another impediment that reduces the attractiveness of EVs to many, and that is the dearth of charging stations. These stations need to be available everywhere – as prevalent as gas stations – before we will see a proliferation of EVs.

The number of EVs is forecasted to rise over the next five years, with significant growth of over 50 percent globally. China is expected to be the leader in this pack. One report predicts EV ownership growth from 500,000 in 2015 to 5 million in 2020. Along with this comes the rapid development of charging stations and charging piles. A charging pile is similar to a charging station where AC power is converted to DC power to charge the battery of the vehicle. However, a charging pile can just be an AC to AC conversion with more focus on diagnostics and monitoring. The ramp of these systems is being accelerated due to new government incentives.

Let’s clarify a few definitions on charging systems. A charging station is also known as an EV charging station, charging pile and charge point. It is part of an infrastructure that supplies electric energy for recharging EVs. There are three main levels when charging an electric vehicle, and all three are important to know before we plug in:

- Level I charging refers to the standard 110VAC outlet that we have in our homes. This is a basic AC-to-DC conversion for powering an EV. However, it takes a long time to charge: five to six hours for a 40-mile-range Chevy Volt, for example. But most drivers plug in at night, go to bed and are fully charged by morning.

- Level II comes in residential and commercial forms. For residential usage, a Level II AC charging station transfers energy at 240VAC and 30A, a level similar to that of a home washer/dryer. These charging stations are built for single-family homes; that is, one user. In commercial usage, Level II not only transfers 240V and 30A but also has a smart network. With a smart network, the owner of a commercial entity can manage the station and run reports on how many EVs are charging in the stations and much more.

- Level III is a DC fast-charging station that can recharge an EV within half an hour. There is no AC-to-DC conversion here. However, the disadvantage today is a lack of standards; there is no standard plug. There are two standards competing in the U.S. and Japan.

So Where Do Charging Piles Come into Play?

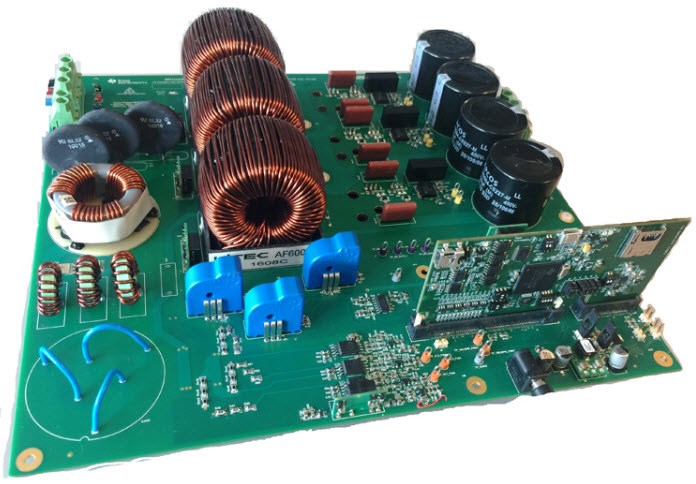

TI’s new subsystem reference design Vienna Rectifier-Based Three Phase Power Factor Correction Reference Design Using C2000™ MCUs for large power transfer and features TI’s C2000™ microcontroller and UCC21520 isolated gate driver and other products in the design.

Vienna rectifiers are developed for large power systems such as 60kW and above. The significance of this reference design is to showcase the value of this rectifier. High-power charging pile systems transfer power significantly faster, typically 30 to 40 minutes. This reference design has an efficiency target of 98 percent with the gate driver as a strong enabler in reducing switching losses. In addition, the C2000 MCU accelerator enables fast control loop execution and the in-built Sigma Delta Demodulators enables accurate current sensing.

Vienna Rectifier-Based Three Phase Power Factor Correction Reference Design Board

Additional Resources:

- Download schematics and design files from EV charging reference designs from TI:

- Learn more about the UCC21520:

- Watch videos about the power of an isolated driver and dynamic performance of a reinforced isolated dual-channel driver.

- Download the application note, "UCC21520: A Universal Isolated Gate Driver with Fast Dynamic Response."

- Read the blog Electric vehicle charging stations are getting smarter and charging faster by TI’s Jayanth Rangaraju.

- New four-part online training series on the Introduction to EV Charging Stations (Piles)

- Introduction to EV Charging (Pile) Station Standards

- EV Charging (Pile) Station Subsystem Analysis

- AC and DC Charging (Pile) Station Design Considerations

- EV Charging Station System Solutions