Multisensor Advanced Driver

Assistance Systems (ADAS)

See advanced driver assistance systems (ADAS).

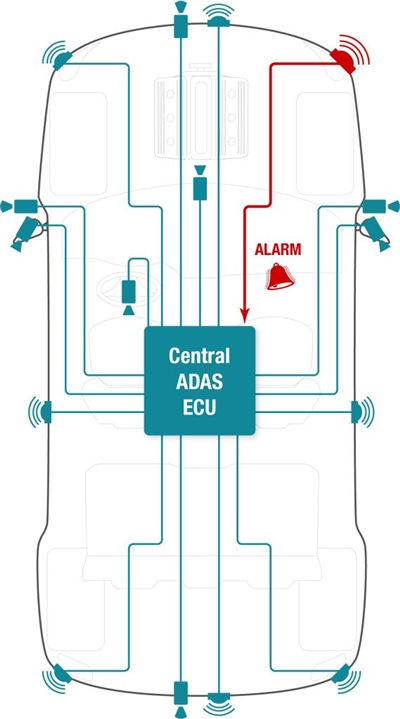

Next-generation vehicles may have a dozen or more remote raw data sensors (Figure 1). Supervising the health status of every sensor increases

software overhead in the central ECU processor. The ECU must monitor factors such as

sensor status, module voltage, module temperature, link operation (in both

directions) and other indicators across multiple sensors, serializers, deserializers

and other chips to generate a complete picture of sensor health. You could add a

small microcontroller to each remote-sensor module for health monitoring and

housekeeping, but this increases module size and cost – and the central ECU must

still examine each sensor and link individually.

Integrating health-monitoring

functions into the SerDes chipset enables collective monitoring of multiple sensor

modules as well as their links, so that the central ECU receives only a single,

consolidated interrupt warning.

Link Status and Protection

The first layer in autonomous sensor monitoring is the link integrity itself. The link must provide a robust control channel as well as link data-protection and diagnostic features. The link monitors cable faults

(open, short to ground, short to Vbatt) as well as bit errors, and reports alerts back to the ECU. Both the forward channel and back channel are supervised by the SerDes chipset for faults. In addition, the DS90UB953-Q1 serializer performs a parity check on data input of the serializer, allowing the system to determine if potential errors originate from the sensor or

from the link. Finally, the deserializer’s adaptive equalizer provides a cable health-quality measurement, enabling the system to warn of cable deterioration.

Sensor Module Health

Diagnostics

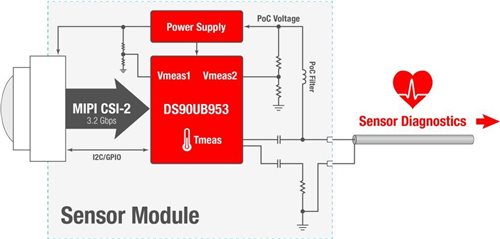

As sensors

proliferate and system functional safety becomes more important, it is useful for

individual sensor modules to provide some level of health monitoring. The DS90UB953-Q1 serializer, for example, incorporates a number of features

to support this goal (Figure 2). Internally, the serializer supervises its own status, such as

lock, valid clock and temperature. The serializer can also monitor external health

factors such as power-supply voltages and incoming sensor data errors. A

configurable alarm bit sent back continually to the deserializer warns the ECU if

any monitored value is out of range. The serializer also reports if there are errors

in the control channel communication to the sensor module. If an I2C

write error arises, the serializer does not propagate erroneous I2C

commands, thus helping to prevent sensor module misconfiguration. The deserializer

delivers a warning to the central ECU so that the system can take further action

such as control data retransmission.

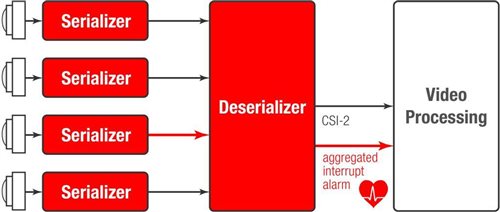

Aggregated Health Status

A multi-input deserializer hub such as the DS90UB960-Q1 aggregates the status of as many as four sensors to a

single programmable open-drain interrupt pin (Figure 3). An alarm sent by any one of the multiple sensor serializers or links can

trigger the interrupt. The local processor then reads the status registers to ascertain the nature and location of the warning. You can configure the deserializer interrupt pin to activate based on a number of programmable variables. Since

the pin uses an open-drain structure, you can connect multiple interrupts together (wire OR’d) to combine interrupts from multiple chips, saving processor I/O pins.

Smart Sensor Health

An

increasing number of high-speed sensors are being used in automobiles, leading the

way to autonomous driving. Today’s raw data sensors can incorporate

health-monitoring features to remotely and autonomously monitor for faults, saving

processor resources and providing an extra layer of system protection. These

“health-smart” modules make it easier to deploy the larger numbers of high-speed

sensors that future vehicles will require. To learn more, check out TI’s entire

FPD-Link III SerDes portfolio for ADAS applications.

Figure 1 Example Deployment of

Automobile Camera and Radar Sensors

Figure 1 Example Deployment of

Automobile Camera and Radar Sensors Figure 2 Example of Integrated Sensor

Module Health Diagnostics

Figure 2 Example of Integrated Sensor

Module Health Diagnostics Figure 3 A Deserializer Hub Aggregates Alarms from Multiple Sensor Links

Figure 3 A Deserializer Hub Aggregates Alarms from Multiple Sensor Links