SSZTBD4 april 2016 DLP9000XUV

Today, the range of applications and markets where advanced light control technology helps solve complex engineering problems is incredibly broad.

This wasn’t always the case.

Back in the late 1980s, the digital micromirror device (DMD) technology we invented was still in its infancy. Ideas like 4K digital movie projection or 3D industrial printing using DLP chips were equipment yet to be invented.

Over the years, that certainly has changed. We put our technology into the hands of key business partners, as well as students, engineers and product developers – and they ran with it. Suddenly, people were constantly asking us what else could be done with DLP technology. To this day, we receive a steady stream of amazing questions from curious problem solvers around the world who are looking to DLP technology for answers.

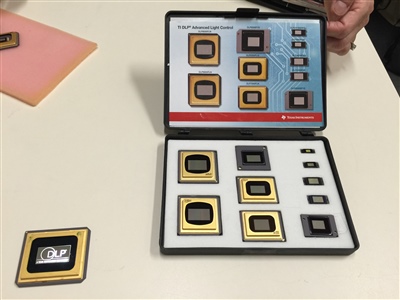

I’m proud to say we’ve answered many of their questions with our family of DLP products, which have been continually tuned and expanded to accommodate a variety of uses no one could have envisioned back when it was invented in 1987.

Here is just a small sampling of the applications customers are solving with DLP technology today:

- In the manufacturing world, the fast speed inherent in DLP technology is used in industrial measuring and sensing to facilitate extremely accurate 3D measurement for areas such as machine vision and factory automation. Imagine a factory, for example, where circuit boards are made in large batches. With solutions based on DLP chips, manufacturers can rapidly scan each board for imperfections significantly faster and more reliably than with more traditional tactile inspection techniques.

- In health care, DLP technology is shedding new light on many established medical practices. Dentists are using DLP technology-powered tools that allow them to perform 3D scans of a patient’s tooth to more quickly create artificial teeth or tooth replicas. In another health-minded twist on DLP technology, devices like the VeinViewer® use harmless near-infrared light and DLP technology to image a patient’s vein location onto their skin, making it far easier for clinicians to administer intravenous (IV) solutions.

- From quality control in food, to pharmaceuticals and beyond, a new class of DLP technology-powered spectrometers are small and reliable enough to provide real time analysis about the characteristics of a given liquid or solid when and where it’s needed. This trend toward hand-held spectroscopy is a huge departure from older systems, which were costly and had to be housed in large laboratories.

Clearly, the advanced light control properties of DLP chips are changing many industries. Two critical properties of DLP technology, speed and wavelength, have made it very useful across a broad spectrum of industrial applications.

Speed is certainly one advantage. In our DLP Products design, millions of micro-electric mirrors, each smaller than the width of a human hair, flip thousands of times every second to shape and control light. This kind of speed and precision is an advantage for industrial applications where companies are always striving to be more efficient and improve measurement or analysis cycle time.

Perhaps less obvious is the wavelength range in which DLP chips can function. They aren’t just limited to controlling visible light. Our products can operate in wavelengths ranging from 363 up to more than 2,500 nanometers, which is particularly useful in applications such as lithography, 3D printing and spectroscopy.

Beyond the inherent technical advantages of DLP technology, I’m very proud of the resources we’ve developed around it and the excitement from our customers. It includes our self-service website filled with great technical information, our portfolio of Evaluation Modules (EVMs), and our DLP Design Network. And, I look forward to evolving our chip solutions as we continue to engage in meaningful two-way conversations with customers, students, product developers and engineers who keep finding innovative new uses for DLP technology.