SSZTBE3 April 2016 LDC1101 , LDC1612 , MSP430FR6989

Inductive proximity sensors can be used for contactless detection of metal in close proximity to an LC sensor. These inductive sensing solutions can enable presence detection and task counting in factory assembly lines without influence from non-conductive materials such as oil, water, dirt or dust. What you may not realize is that the ultra-low-power MSP430FR6989 microcontroller (MCU) includes an integrated extended scan interface (ESI) peripheral that can be used as an analog front end (AFE) to connect directly to a PCB coil for low-cost and low-power inductive proximity sensing.

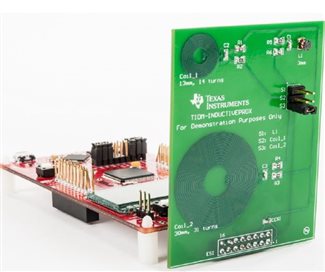

LC sensors are commonly used in applications involving inductive sensing. After charging the capacitor with a short pulse, the LC sensor oscillates and the signal voltage will decay. Metal objects cause the signal to decay quicker due to energy absorption by Eddy currents within the metal. This quicker decay enables for detection of metals coming within proximity of the sensor. The TI Design reference design TIDM-INDUCTIVEPROX showcases the hardware and software needed to leverage the advanced ESI peripheral in a single chip inductive proximity sensing implementation. This solution is also extremely energy efficient, requiring only micro amps of current. In this configuration, the integrated analog front end is used to stimulate LC sensors, senses the signal levels and converts them to a digital representation. This data is then stored in a pre-processing unit for analysis via a processing state machine.

This type of application can be implemented on an MSP-EXP430FR6989 MCU LaunchPad™ development kit by connecting a LC sensor to the ESI pins at the bottom of the board. The TI Design reference design mentioned above showcases multiple LC sensor variants to demonstrate the impact on frequency and decay rate of the output signal.

If an application that requires higher resolution (i.e. to determine exact distance of metal vs. simply detect if metal comes within range), an inductive-to-digital converter like the LDC1612 or LDC1101 can be added to the system. With this two-chip solution, the MSP430FR6989 microcontroller can be used to keep the system in standby until metal is detected, and then can wake up the high resolution LDC IC to capture precise measurements.

Checkout the video below for a demo pairing the LDC1000 IC with the MSP430™ MCU:

Low-Power Inductive sensing with MSP and LDC