SSZTCF9 july 2015 LM26420 , LM43603

Industrial power design engineers face a lot of power challenges; one of the main ones is large variation in input-voltage ranges. This is caused by many reasons, including the remoteness of designs. For example, factories will have a main voltage rail that can be transmitted across the whole building. These long rails can cause voltage drops due to impedances, as well as induced voltages and noise caused by equipment that’s either attached to the supply in different locations or heavy collapsing loads with large inductive and capacitive elements.

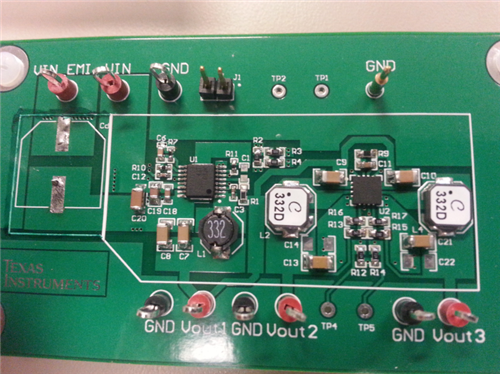

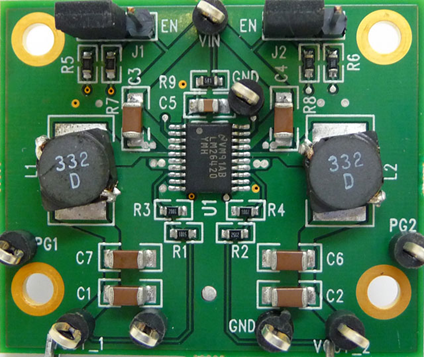

The reference design in Figure 1 is a single-input step-down converter with three low-noise outputs. The module uses the LM43603, a SIMPLE SWITCHER® synchronous step-down DC/DC converter capable of driving up to 3A of load current from an input voltage ranging from 7V to 36V. The 5V output from the LM43603 enables the LM26420 DC/DC regulator (see Figure 2), which further steps down this voltage to produce 1.8V and 2.5V outputs capable of driving 1A load current each. This power supply is suitable for applications that require multiple outputs from a single-input DC voltage. It provides good regulation performance over an input-voltage range of 7V to 36V.

Using a combination of fully synchronous switching regulators and good layout techniques, it is possible to develop such a compact solution. The main reason why it is so important to have low-noise solutions is because you don’t want to add to the original problem of a noisy supply. If the power supply has the capability to work over a wide range, it gives industrial engineers a chance to overcome the varying voltage-input range, while also giving them the ability to “cut and paste” across multiple different backplanes with different ranges like 12VIN or 24VIN. This makes the design easier and also enables overall faster time to market and cost reductions.

Low-noise solutions make it easier to expand the number of designs connected to the main backplane without additional headache.

Figure 2 The LM26420 Dual DC/DC Converter

Figure 2 The LM26420 Dual DC/DC ConverterReferences:

- Get more information on all of TI’s DC/DC power products.

- Consider the LM26420 and LM43603 for your next power supply design.

- Download the wide VIN low noise triple output step-down converter reference design.

- Find out more about TI’s products for industrial applications.