ZHCSE14D June 2015 – June 2018 LMT01

PRODUCTION DATA.

- 1 特性

- 2 应用

- 3 说明

- 4 修订历史记录

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 Electrical Characteristics

- 6.6 Electrical Characteristics - TO-92/LPG Pulse Count to Temperature LUT

- 6.7 Electrical Characteristics - WSON/DQX Pulse Count to Temperature LUT

- 6.8 Switching Characteristics

- 6.9 Timing Diagram

- 6.10 Typical Characteristics

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11器件和文档支持

- 12机械、封装和可订购信息

8.1.1 Mounting, Temperature Conductivity, and Self-Heating

The LMT01 can be applied easily in the same way as other integrated-circuit temperature sensors. It can be glued or cemented to a surface to ensure good temperature conductivity. The temperatures of the lands and traces to the leads of the LMT01 also affect the temperature reading, so they must be a thin as possible.

Alternatively, the LMT01 can be mounted inside a sealed-end metal tube, and then can be dipped into a bath or screwed into a threaded hole in a tank. As with any IC, the LMT01 and accompanying wiring and circuits must be kept insulated and dry to avoid excessive leakage and corrosion. Printed-circuit coatings are often used to ensure that moisture cannot corrode the leads or circuit traces.

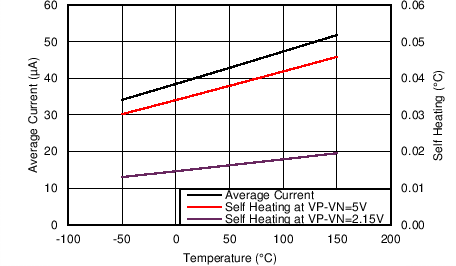

The junction temperature of the LMT01 is the actual temperature being measured by the device. The thermal resistance junction-to-ambient (RθJA) is the parameter (from Thermal Information) used to calculate the rise of a device junction temperature (self-heating) due to its average power dissipation. The average power dissipation of the LMT01 is dependent on the temperature it is transmitting as it effects the output pulse count and the voltage across the device. Equation 4 is used to calculate the self-heating in the die temperature of the LMT01 (TSH).

where

- TSH is the ambient temperature

- IOL and IOH are the output low and high current level, respectively

- VCONV is the voltage across the LMT01 during conversion

- VDATA is the voltage across the LMT01 during data transmission

- tCONV is the conversion time

- tDATA is the data transmission time

- PC is the output pulse count

- RθJA is the junction to ambient package thermal resistance

Plotted in the curve Figure 27 are the typical average supply current (black line using left y axis) and the resulting self-heating (red and violet lines using right y axis) during continuous conversions. A temperature range of –50°C to +150°C, a VCONV of 5 V (red line) and 2.15 V (violet line) were used for the self-heating calculation. As can be seen in the curve, the average power supply current and thus the average self-heating changes linearly over temperature because the number of pulses increases with temperature. A negligible self-heating of about 45m°C is observed at 150°C with continuous conversions. If temperature readings are not required as frequently as every 100 ms, self-heating can be minimized by shutting down power to the part periodically thus lowering the average power dissipation.

Figure 27. Average Current Draw and Self-Heating Over Temperature

Figure 27. Average Current Draw and Self-Heating Over Temperature