ZHCSLA3A May 2020 – December 2020 LM7481-Q1

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

- 8 Detailed Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical 12-V Reverse Battery Protection Application

- 9.2.1 Design Requirements for 12-V Battery Protection

- 9.2.2 Automotive Reverse Battery Protection

- 9.2.3 Input Transient Protection: ISO 7637-2 Pulse 1

- 9.2.4 AC Super Imposed Input Rectification: ISO 16750-2 and LV124 E-06

- 9.2.5 Input Micro-Short Protection: LV124 E-10

- 9.2.6 Detailed Design Procedure

- 9.2.7 MOSFET Selection: Blocking MOSFET Q1

- 9.2.8 MOSFET Selection: Hot-Swap MOSFET Q2

- 9.2.9 TVS selection

- 9.2.10 Application Curves

- 9.3 Do's and Don'ts

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

9.2.6.4 Hold-up Capacitance

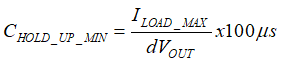

Usually bulk capacitors are placed on the output due to various reasons such as uninterrupted operation during power interruption or micro-short at the input, hold-up requirements for doing a memory dump before turning of the module and filtering requirements as well. This design considers minimum bulk capacitors requirements for meeting functional status "A" during LV124 E10 test case 2 100-µs input interruption. To achieve functional pass status A, acceptable voltage droop in the output of LM74810-Q1 is based on the UVLO settings of downstream DC-DC converters. For this design, 4.0-V drop in output voltage for 100 µs is considered and the minimum hold-up capacitance required is calculated by

Minimum hold-up capacitance required to hold output with 4.0-V drop at 18-A current for 100 µs is 450 µF. A 470-uF electrolytic capacitor is a closest standard value that can be placed at the output. Note that the typical application circuit shows the hold-up capacitor as optional because not all designs require hold-up capacitance.