-

Create an Intelligent Building System: Use mmWave to Count and Track People

Create an Intelligent Building System: Use mmWave to Count and Track People

How amazing would it be if the buildings were smart – I mean truly smart? Imagine if a commercial building could tell you where people are located, where they are going, and whether or not they are safe. This could revolutionize building systems. Video cameras could turn on and record only when needed; lighting and heating, ventilation and air-conditioning (HVAC) systems could more efficiently handle occupancy; elevators could skip stopping at particular floors if there are already too many people in the elevator car. Imagine if automated doors opened, just like in “Star Trek,” only when a person intended to walk through it.

Just as intelligent autonomy (with autonomous cars, drones and robots) is set to revolutionize the way people and materials move, the buildings of the future will use sensor-driven intelligence to automatically adjust their systems to increase efficiency, improve comfort and reduce waste. Detecting peoples’ position and tracking their movement indoors and outdoors is a key sensing capability that will enable more intelligent systems, creating smart, efficient, automated buildings of the future.

Today’s sensing technologies in the building automation space – passive infrared (PIR), video cameras and active infrared (LIDAR, 3-D time of flight) – all have challenges in terms of accuracy, privacy, environmental robustness and system complexity that prevent them from being able to effectively meet truly smart levels of capability.

TI’s millimeter wave (mmWave) technology has created radar-based sensors that can overcome sensing challenges in building automation. TI’s mmWave technology inherently provides a point cloud of position and velocity information of objects in view. Because the technology uses high radio frequencies, the sensing is robust to challenging outdoor conditions such as dazzling sunlight, darkness, fog, smoke and precipitation. The technology can also sense through plastics and drywall and can thus be hidden in some installations, or enable cleaner industrial designs.

TI’s mmWave sensors can solve indoor people-counting applications as well. Figure 1 shows an example of the output of the mmWave sensor, which is tracking the location of multiple people simultaneously, while ignoring the tables and chairs.

Figure 1 An Example Indoor Location

Output Generated from the mmWave Sensor, Which Is Tracking the Location of

Multiple People Simultaneously Relative to the Two Boxes Indicated on the

Ground

Figure 1 An Example Indoor Location

Output Generated from the mmWave Sensor, Which Is Tracking the Location of

Multiple People Simultaneously Relative to the Two Boxes Indicated on the

GroundIntegrated hardware processing and DSP cores that are onboard TI’s IWR6843 mmWave sensors enable complete edge processing without the need for a complex system topology or an expensive external processor.

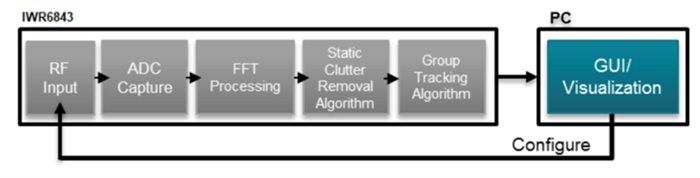

For people counting applications (see the block diagram shown in Figure 2), the IWR6843 handled all of the software needed to track and count. No external processor is necessary, and a PC is only used in the demo for visualization and configuration.

Figure 2 The People Counting Demo Using

the IWR6843 Incorporates All Processing and

Calculation Necessary for People Tracking and Static Clutter Removal Onboard the

IWR6843, Reducing System Complexity and

Eliminating the Need for an External Processor

Figure 2 The People Counting Demo Using

the IWR6843 Incorporates All Processing and

Calculation Necessary for People Tracking and Static Clutter Removal Onboard the

IWR6843, Reducing System Complexity and

Eliminating the Need for an External ProcessorThe People Tracking and Counting Reference Design Using mmWave Radar Sensor shows how this demo works and how to replicate it using the IWR6843 evaluation module (EVM). TI provides source code, including all fundamental software building blocks, libraries and algorithms as source, in the mmWave software development kit (SDK) and the People Counting Lab on TI Resource Explorer. The demo even includes multiple examples that support use cases up to 6m and 14m.

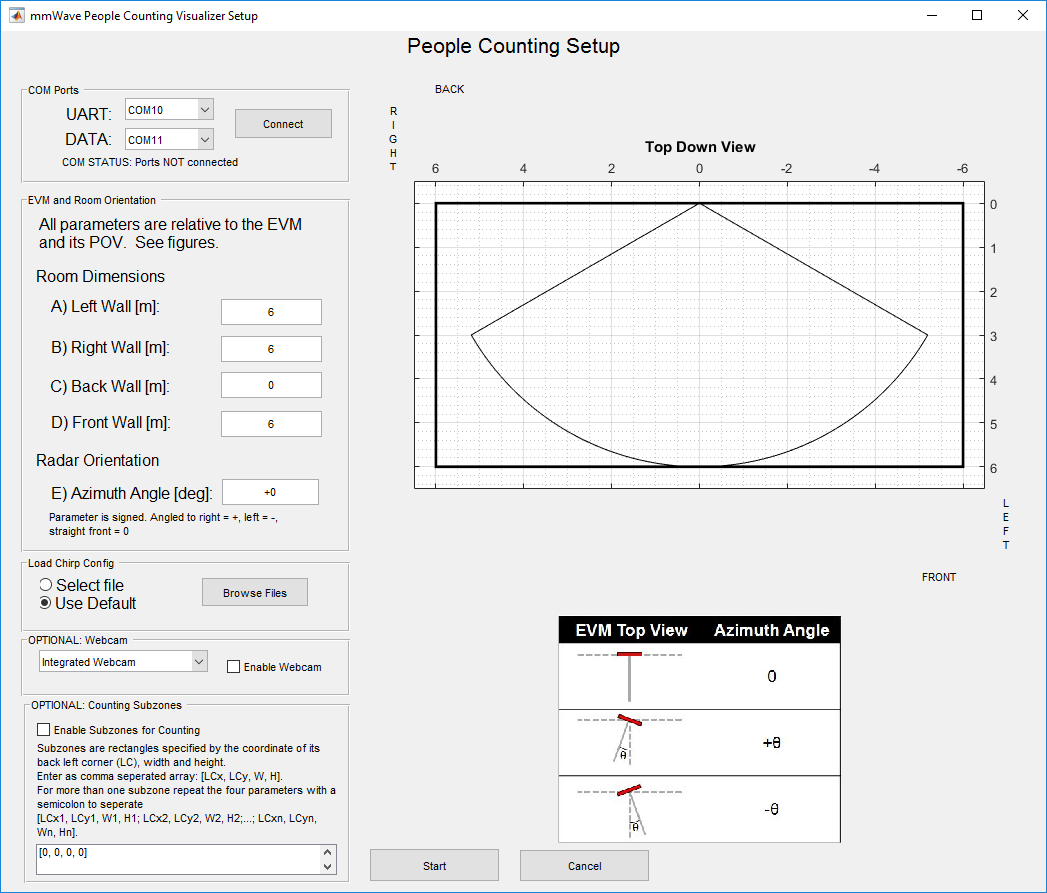

If these examples don’t quite meet your use-case requirements, you can use the built-in configuration tool shown in Figure 3 or follow the Tuning Guide to dial in the performance.

Figure 3 You Can Use the PC

Visualization Tool for the People Counting Demo to Configure the Area and

Counting Zones for Detection; the MATLAB-based Source Code for This Tool Is

Provided as Reference in TI Resource Explorer

Figure 3 You Can Use the PC

Visualization Tool for the People Counting Demo to Configure the Area and

Counting Zones for Detection; the MATLAB-based Source Code for This Tool Is

Provided as Reference in TI Resource ExplorerIn the future, we at TI see the C674x digital signal processor (DSP) on the IWR6843 enabling additional algorithms for building automation applications such as filtering and classification. Imagine if a motion detection system could ignore the profile of objects like trees moving in the wind or leaves blowing on the ground, or classify the presence of an animal scurrying around versus a person. By enabling detection at the edge to determine whether an object should be tracked, this capability would reduce false detection in building automation systems. mmWave technology provides a wealth of information in terms of range, velocity, angle, size and reflectivity that can be used with the onboard C674x DSP to enable these types of capabilities in a single-chip solution.

Additional Resources

- Learn more about building automation applications in mmWave.

- Read about the very fine motion detection vs. PIR experiment on TI Resource Explorer.

- Experiment with people counting through plastic, drywall, and wood experiment on TI Resource Explorer.

- Watch people tracking and motion detection using mmWave for building automation in action.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated