-

Protecting Field Transmitters from Surge Transients

Protecting Field Transmitters from Surge Transients

If you are a designer working on field transmitters, you are probably thinking about the physical environment where the system will be installed. Industrial sensor applications require a robust protection scheme since they are likely to encounter damaging surges created by lightning, ground loops, electrostatic discharge (ESD) and electrical fast transient (EFT) bursts. These high surge events could lead to induced voltages onto cables causing large voltage spikes to appear on circuits that were never designed to handle them.

In this post, I will discuss the major challenges when selecting transient voltage suppression (TVS) diodes for ESD and surge protection for field transmitters.

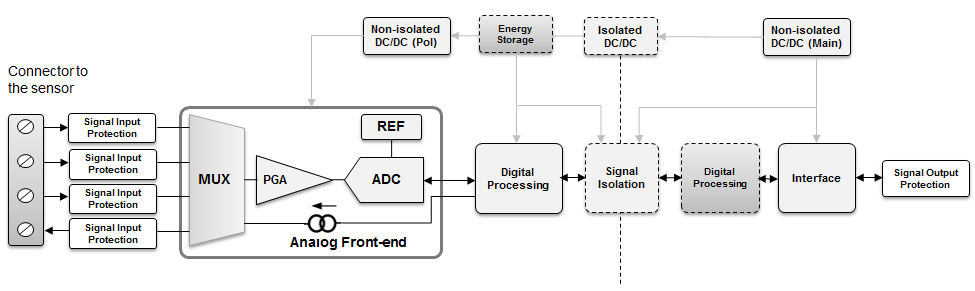

In factory automation and process control, a field transmitter measures critical parameters such as temperature, pressure and flow from the input signal of a sensor. It then converts the measurement into an accurate electrical representation that is transmittable through a robust interface/field bus to the programmable logic controller (PLC) or central unit. Some of the most common communication protocols for field transmitters are IO-Link in factory automation and 4-20mA/Highway Addressable Remote Transducer (HART) loop interfaces in process automation. Figure 1 shows a high-level block diagram of a temperature transmitter, including the signal input/output (I/O) protection.

Figure 1 Temperature Transmitter Block

Diagram

Figure 1 Temperature Transmitter Block

DiagramAs with all systems with an externally exposed interface, your system must have International Electrotechnical Commission (IEC) 61000-4-2 ESD and IEC 61000-4-5 surge protection. The IEC 61000-4-5 surge standard is the most severe transient immunity test in terms of higher current and longer duration, and its application is often limited to long signal and power lines.

Clamping Voltage

In field transmitter applications, there are several downstream components that need to be protected, including multiplexers, analog-to-digital converters (ADCs), 4-20mA transceivers and low drop out (LDO) regulators. Unfortunately, integrated circuit (IC) data sheets generally do not provide a transient voltage immunity rating, which makes it harder to select the right solution to robustly protect your system.

The clamping voltage is the lowest voltage level that your system needs to survive when the TVS diode is providing protection. In other words, it measures how well your protection solution can clamp a transient voltage. The lower the clamping voltage, the better the protection, and the more protection margin you will have for your downstream components. Typical TVS diodes clamp at voltages too high to protect your system, requiring the selection of downstream system components with higher voltage-tolerance ratings, increasing system cost and board area. Therefore, it is recommended to choose a TVS solution with low and flat clamping voltage technology to robustly protect your system.

Package Size

A typical requirement for industrial field transmitters is to be tested for (and to withstand) 25A (8/20µs) at 1kV, with a 42Ω coupling network during the IEC 61000-4-5 surge immunity test. With such a high power rating, the TVS diode must be able to dissipate and divert high-voltage transients to ground; therefore, you would need to adopt a big solution size that could handle the high power dissipation, resulting in increased board space and design complexity.

Take for example the IO-Link Sensor Transmitter Reference Design (Figure 2), where a big portion of the board space is occupied by traditional TVS diodes used for signal I/O protection, which take up 12.5mm2 of board space for SMA industry standard packages and up to 19.1mm2 for SMB packages. Adopting a small form factor TVS solution saves board space and allows for a much closer placement to the connector in order to keep EMI outside the board area.

Figure 2 Sensor Transmitter Reference

Design Board

Figure 2 Sensor Transmitter Reference

Design BoardLeakage Current

In addition to clamping voltage and package size, leakage current poses yet another challenge when considering TVS diodes for field transmitter applications. At the working voltage, when the diode is not operating in its breakdown region, some current will flow through the diode and can affect system accuracy. Leakage current on the data line negatively impacts signal integrity; therefore, lower leakage enables higher-accuracy 4-20mA current-loop measurements and is necessary in order to prevent offset on 4-20mA loop interfaces.

TI’s new precision surge protection clamp can help solve all three of the surge-protection challenges I’ve described in this post. The TVS3300 can provide up to 30% lower and flatter clamping voltage, a 94% smaller footprint and 58% lower leakage current than traditional SMA and SMB TVS diodes in the market.

Additional Resources

- Download the TVS3300 data sheet.

- Start designing now with the TVS3300 evaluation module.

- Check out the Surge Protection Reference Design for PLC Analog Input Module.

- Watch the Precision Surge product training video.

- Order SMA/SMB drop-in replacement adapter boards.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated