-

How Processing in Real-time Drives High-performance Power Systems SSZT063 october 2022 TMS320F2800137 , TMS320F280025C , TMS320F280039C , TMS320F280049C , TMS320F28075 , TMS320F28379D

-

How Processing in Real-time Drives High-performance Power Systems

How Processing in Real-time Drives High-performance Power Systems

Meghana Manavazhi

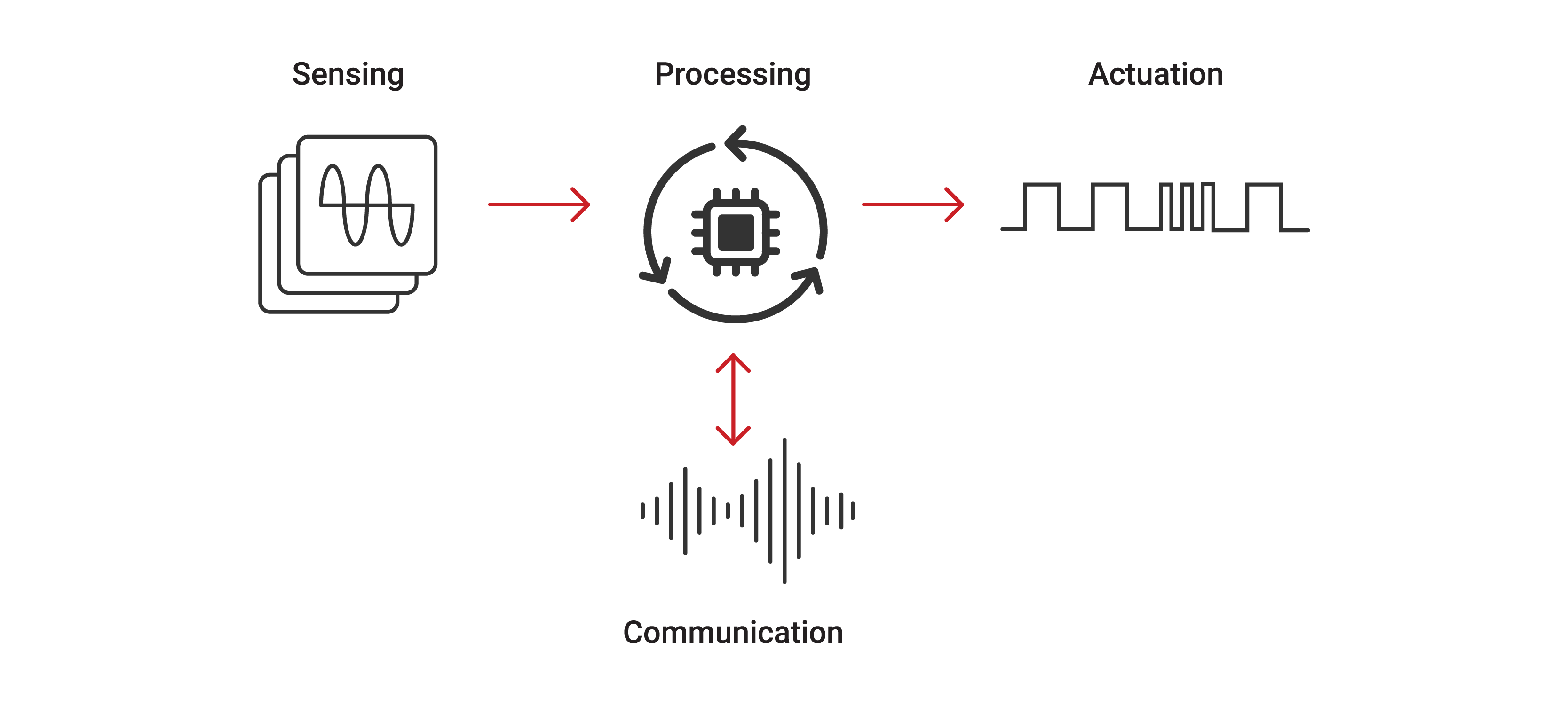

The previous installment of this real-time control series focused on the sensing functional block of the real-time control signal chain (Figure 1). It’s easy to misunderstand the second functional block, processing, and assume that it is only tied to the core central processing unit (CPU) frequency or million instructions per second (MIPS), focusing purely on data crunching. In this series installment, I’ll demonstrate the value of processing through the lens of high-performance power systems, and dispel any misconceptions about the role of processing in real-time control systems.

Figure 1 A Real-time Control Signal

Chain

Figure 1 A Real-time Control Signal

ChainGrowing energy utilization – especially in grid infrastructure and power delivery applications – demands efficient, compact and stable power systems. This requirement has given rise to an evolution in power-conversion systems to deliver high power efficiency, a fast transient response and high power density with larger power capacity.

High Power Efficiency

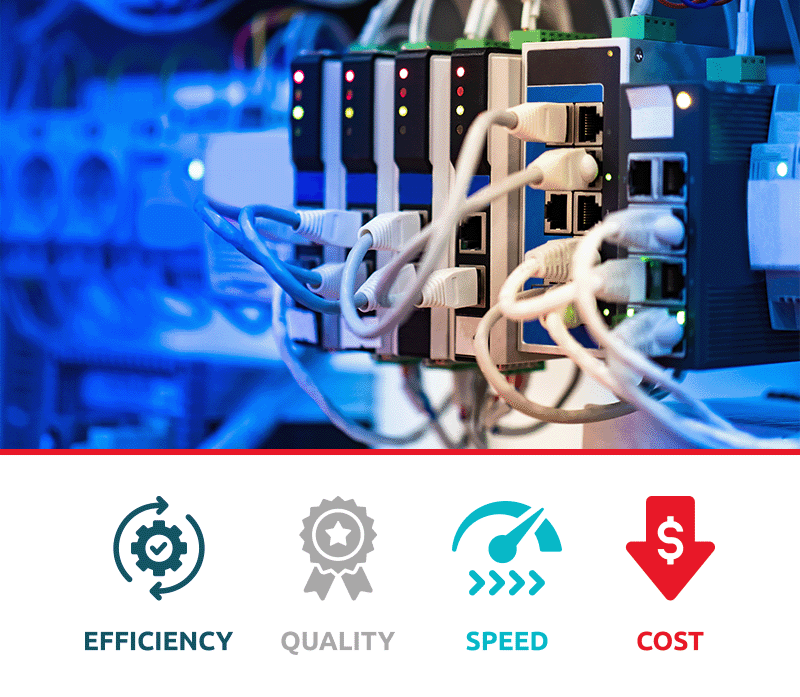

As shown in Figure 2, uninterruptible power supplies in data centers must operate continuously. Enhancements in efficiency, as discussed in the white paper, "Achieve Power-Dense and Efficient Digital Power Systems by Combining TI GaN FETs and C2000™ Real-Time MCUs," can quickly bring substantial financial savings, a reduction in solution size through smaller heat sinks, and lower greenhouse gas emissions. It can be challenging, however, to implement complex power topologies such as totem-pole bridgeless power factor correction (which uses less passive-energy-dissipating devices) or soft-switching controls such as zero voltage switching and zero current switching that are needed to achieve these benefits.

High performance real-time microcontrollers (MCUs) – some even with on-chip hardware accelerators – can enable the fastest control loops to make this happen. To take this to the next level, real-time MCUs equipped with fast on-chip analog-to-digital converters (ADCs) and tailored post-processing capabilities can further process accurate, fast sampling and the conversion of currents and voltages to reduce overall latency of the real-time signal chain.

Figure 2 Performance Drivers of Uninterruptible Power Supplies in Data Centers

Figure 2 Performance Drivers of Uninterruptible Power Supplies in Data CentersA Fast Transient Response

Server power applications require stable and reliable operation under changing load conditions, for which a fast transient response is a necessity. Several control schemes can enable fast response times. One such scheme is demonstrated in the 1-kW Reference Design with CCM Totem-Pole PFC and Current-Mode LLC Realized by C2000™ and GaN, where the target is to demonstrate fast response times (the target slew rate today being close to 2.5 A/µS to 5 A/µS). Real-time MCUs make ultra-low latency between sensing and actuating a reality by defining fast processing with high CPU frequency/MIPS, quick access to peripheral registers, a fast interrupt response, an optimized control code instruction set, tight hardware coupling of the pillars of the real-time signal chain, and purpose-built logic (pulse-width modulators [PWMs] and comparators) outside the CPU for fault- or fail-detection responsiveness when restricting undershoot or overshoot conditions.

High Power Density

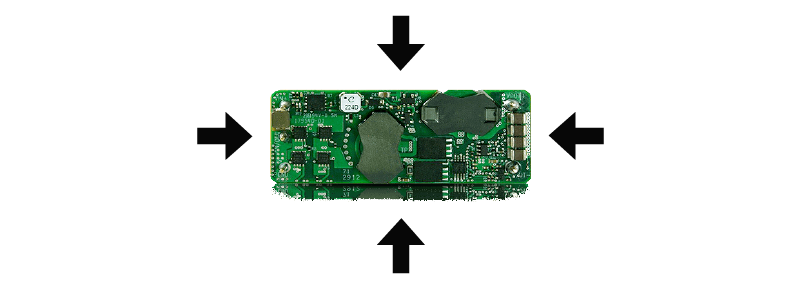

Figure 3 shows the DC/DC converters often required to meet larger power capacity in a smaller space, not only to reduce system costs but to meet regulatory standards such as the Distributed-Power Open Standards Alliance (target being as low as a 1/32 format footprint (0.69 sq in.)). At miniature form factors, reducing heat dissipation without heat sinks becomes a challenge, and adopting wide-bandgap power devices such as gallium nitride and silicon carbide to enable higher switching frequencies and meet these small design sizes can be even more cumbersome. With their inherent architecture and on-chip math enhancers, the processing power of real-time MCUs make complex time-critical data calculations possible. The extra horsepower provides additional computation capability, encapsulating more functions like reducing active noise and thus the electromagnetic interference filters, highlighted as one of many solutions in the white paper, "Understanding the Trade-offs and Technologies to Increase Power Density." Furthermore, customized PWM and comparator modules (beyond the core processing element), with features such as high resolution, blanking window, delayed trip, slope compensation for peak current-mode control, and other functional pieces like the configurable logic blocks, can further enhance processing power.

Figure 3 DC/DC Converters with Reducing Form-factor Trends

Figure 3 DC/DC Converters with Reducing Form-factor TrendsHow Do Real-time MCUs Enable the Necessary Processing Power?

Empowering today’s high-performance power systems effectively is what differentiates the controllers. TI real-time MCUs offer dual memory access, single-cycle deterministic execution, eight-phase parallel pipeline buses, superior memory execution throughput, efficient accelerators and a unified memory map. Some of them also possess co-processors or multicore support to flexibly implement power systems, along with headroom to implement security, diagnostics, adaptive algorithms and housekeeping tasks. See the application note, "Real-Time Benchmarks Showcasing C2000 Control MCU’s Optimized Signal Chain," for further insight.

Conclusion

Although complex control algorithms enable power systems with low THD, high power density and efficiency, and fast transients, actual implementation requires more than just math functionality and higher megahertz speeds from the controller. Since the timing from sensing to actuation also plays a crucial role in defining performance, real-time MCUs designed purposely for ultra-low latency with high CPU performance, flexible PWMs and fast accurate sensing can meet comprehensive system needs today, along with scalable solutions for tomorrow.

To learn more about the actuation functional block of real-time control, read the next article in this series, "How to achieve efficient, reliable and accurate actuation in real-time motor control systems."

Additional Resources

- Find design resources, interactive block diagrams and devices specific to industrial power delivery applications on TI’s Power Delivery page.

- Check out the "Real-Time Control Reference Guide."

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated